Composite Plates – Lightweight, Stiff and Strong!

Ensinger presents new continuous fibre-reinforced thermoplastic plates for industry!

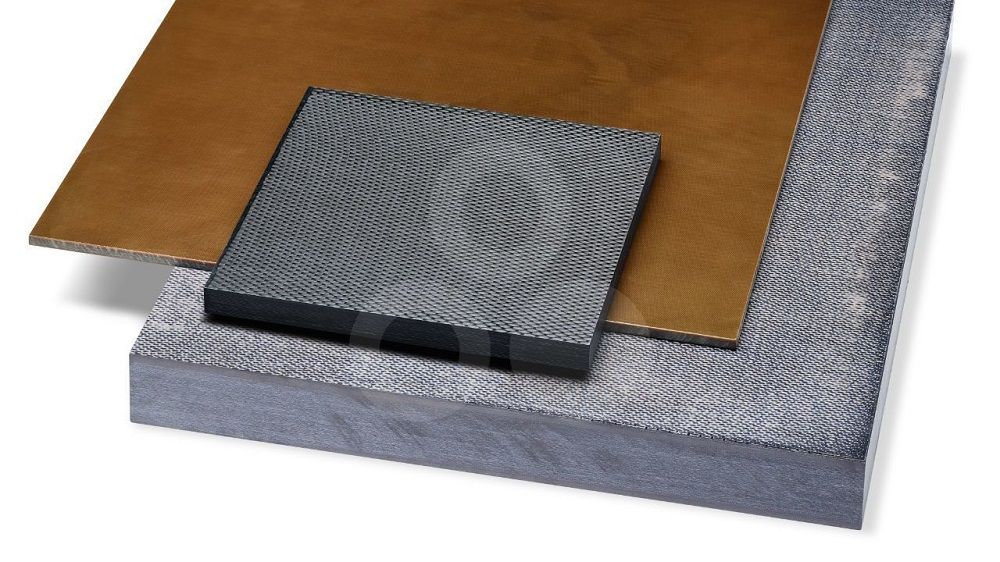

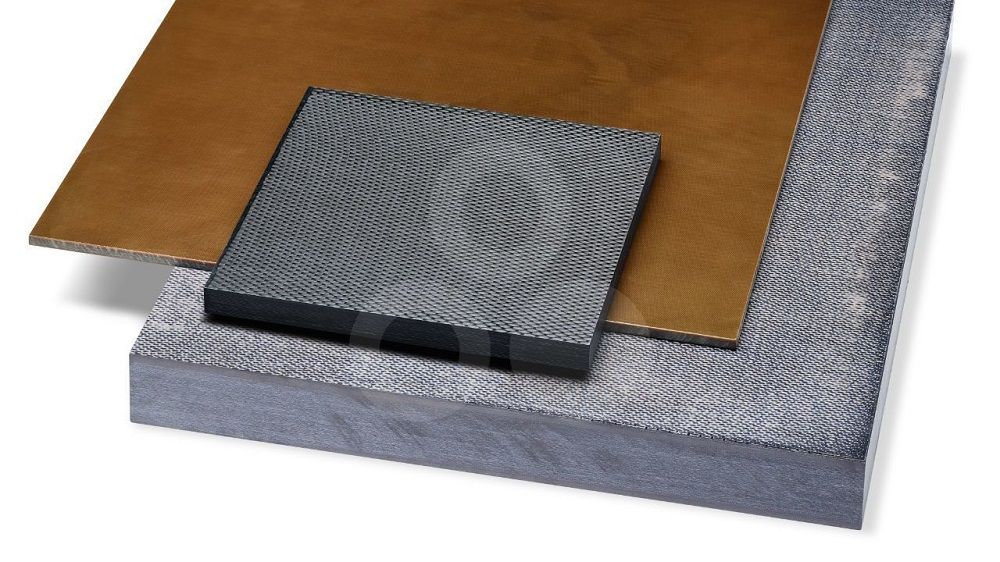

For applications where the mechanical requirements are too high for unreinforced or short fibre-reinforced plastic stock shapes, continuous fibre-reinforced thermoplastic composite plates offer an excellent alternative.

Thanks to the continuous fibre reinforcement, usually a woven fabric of glass or carbon fibres, they have mechanical properties otherwise achieved only by metallic materials.

At the same time, they are significantly lighter than most metal-based alternatives.

Through the use of thermoplastic matrix materials, the plates nevertheless have the same advantages as unreinforced plates made from thermoplastic materials: high impact strength, constant properties over a broad temperature range, chemical resistance and high elongation at break.

By selecting a suitable matrix material, a wide range of customer needs can be met.

Plates made from continuous fibre-reinforced thermoplastics can be processed into finished parts of outstanding quality with minimal tolerances.

Alongside water jet cutting, conventional processing methods are also suitable – assuming suitable facilities and processing parameters.

Three new materials available in the Ensinger composites range

We are pleased to announce that Ensinger has widened its portfolio of composite plates to include three new materials.

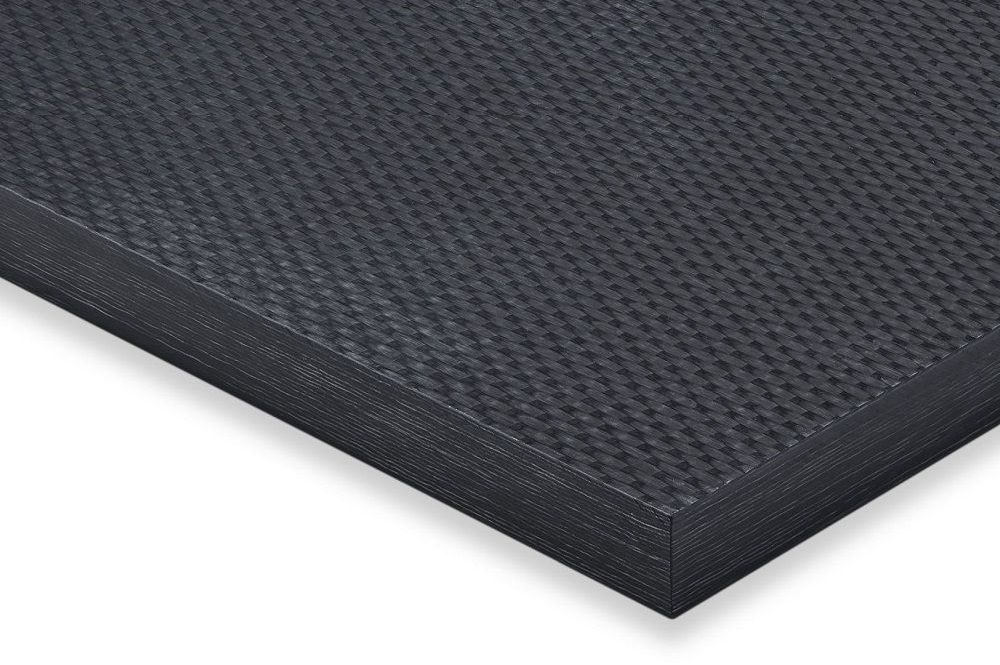

TECATEC PPS CW50 black (PPS CFK – Polyphenylene sulfide, carbon fibre-reinforced)

✔️ Excellent high-temperature resistance

✔️ High strength

✔️ Very good chemical resistance

✔️ High creep resistance

✔️ Good electrical insulation

✔️ Very good dimensional stability over a broad temperature and humidity range

✔️ Carbon fibre reinforcement increases stiffness and strength

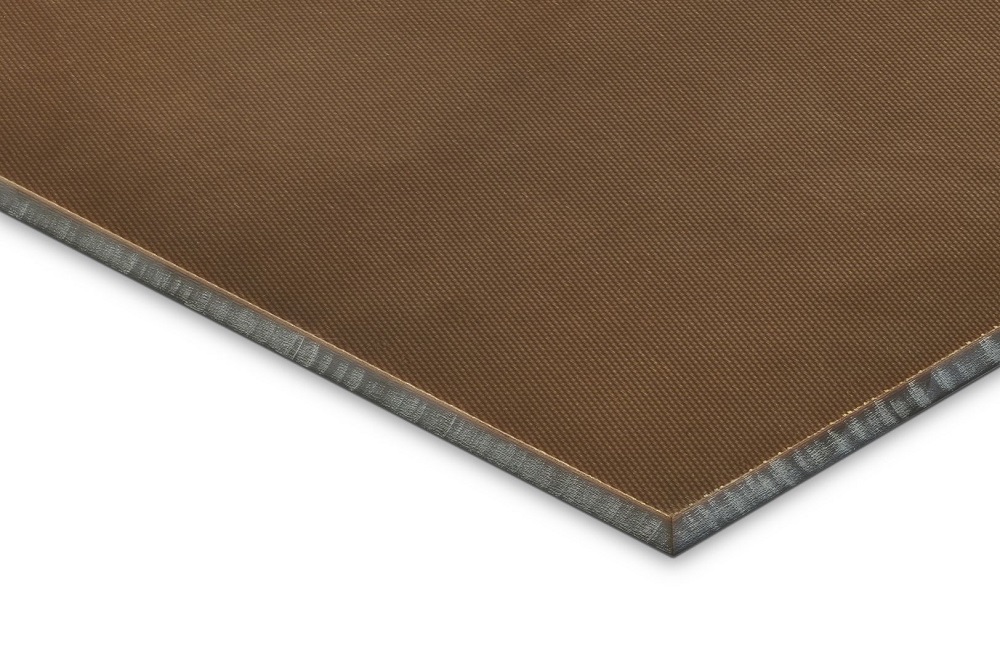

TECATEC PEI GW50 natural (PEI GFK – Polyetherimide, glass fibre-reinforced)

✔️ High continuous service temperature (170°C)

✔️ Good electrical insulation

✔️ High creep resistance over a broad temperature range

✔️ Good radiation resistance

✔️ Good chemical resistance

✔️ Fire, smoke and toxicity retardant (FST)

✔️ Glass fibre reinforcement increases the mechanical properties while keeping costs down

TECATEC PC CW50 black (PC CFK – Polycarbonate, carbon fibre-reinforced)

✔️ Outstanding appearance thanks to crystal-clear, transparent matrix

✔️ High impact toughness

✔️ Excellent machinability

✔️ Constant stiffness over a broad temperature range

✔️ Carbon fibre reinforcement increases stiffness and strength

Made to measure composite plates

Ensinger produces the thermoplastic composite plates to customer-specific requirements, with maximum dimensions of 525 x 625 mm.

Flexible plate thicknesses are available in the range 0.5 to 95 mm, any thickness though is possible.

Standard products are PEI with reinforcing woven glass fibre as well as PC and PPS with woven carbon fibre.

Other matrix and fibre combinations, fibre architectures or customer-specific fibre lay-ups can be provided on request.

As light as plastic, as stiff and strong as metal

The new composite plates from Ensinger have densities between 1.5 and 1.8 g/cm³, giving them a similar specific weight to unreinforced or short fibre-reinforced plates.

Nevertheless, the reinforcing fibres increase their mechanical properties dramatically to a level similar to metal.

Compared with unreinforced polymer plates, continuous fibre-reinforced plates achieve values that are 5 times higher for both tensile strength and Young’s modulus.

Outstanding mechanical properties

The thermoplastic matrix gives the plates high impact toughness, with the value significantly higher than in plates with a thermoset matrix such as epoxy or phenolic resins.

Moreover, the high elongation at break of the thermoplastics ensures tough, non-brittle fracture behaviour.

For some applications, the intrinsic vibration damping of the matrix can also be a relevant advantage.

Fields of application

Applications for continuous fibre-reinforced thermoplastics include the aerospace industry, mechanical engineering, the automotive industry and the sports equipment sector.

In particular for the manufacture of prototypes and small batches, stock shapes are of interest as an affordable option for making small quantities.

Examples of Ensinger composite plates in real-world applications

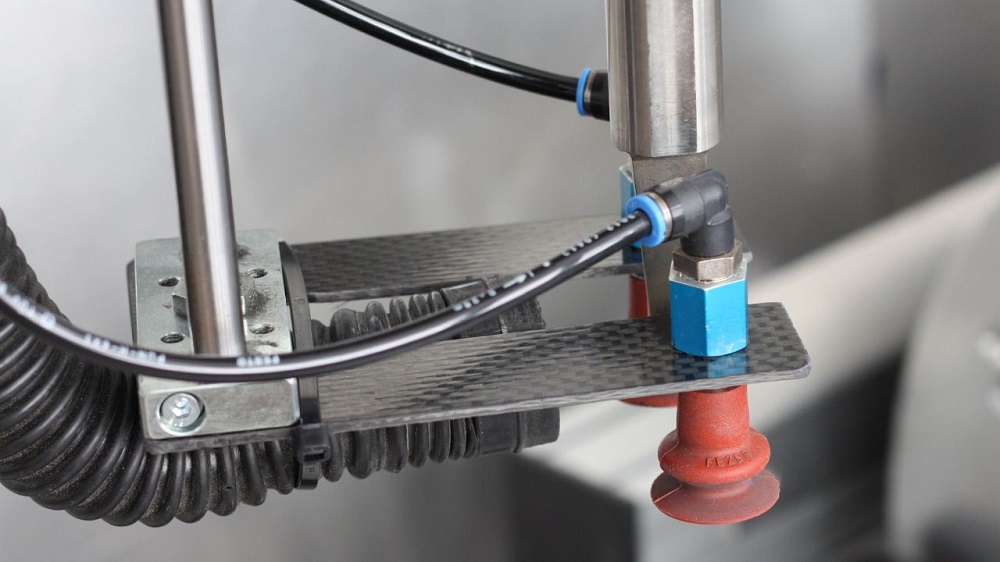

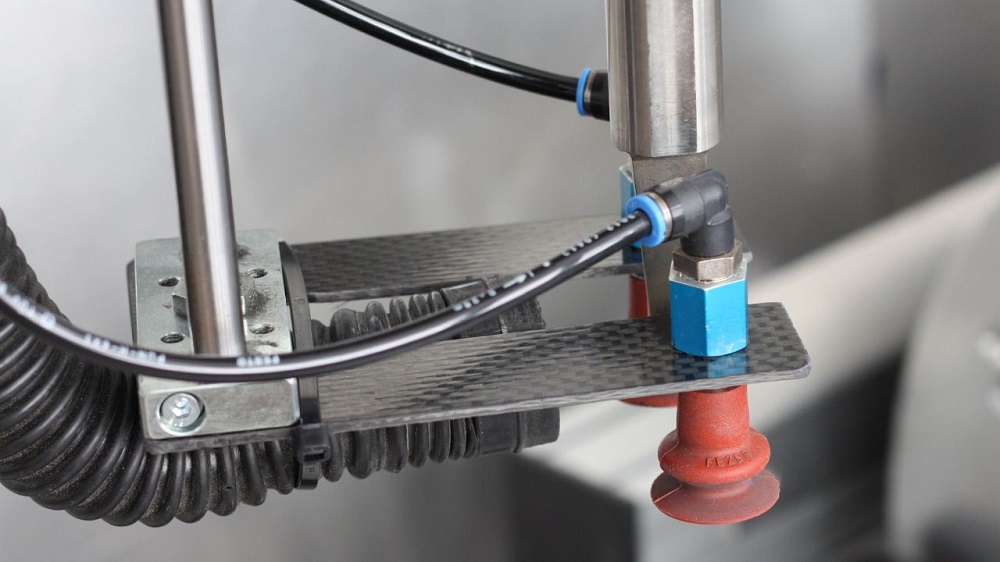

Robotic gripper for a handling device

Advanced automation often requires customised solutions, in particular for the heads of robots. Typical applications are automated solutions for handling devices and respectively their components such as the grippers.

Structural component for an airplane seat (J-hook)

The aircraft industry prevails the highest requirements for installed materials: Low weight, high mechanical properties, fatigue resistance as well as stringent FST requirements are mandatory.

Structural part for a light airplane (Winglet structure)

Structural airplane parts ensure planes spend every possible minute up in the air.

Every part must always work without fault and since in the aerospace industry every single gram is of importance, excessive weight reduces the payload and increases the fuel consumption.

One example of these parts are so called “Winglet structures”, which are used at the tip of the wing of light airplanes or unmanned aerial vehicles (UAV).

Thank you Ensinger GmbH

We wish to extend our thanks to our valued international supplier Ensinger GmbH for your support and allowing Supply Services Limited to use your marketing materials.

In the field of thermoplastic composites, Ensinger has outstanding design and engineering experience in development and manufacturing of parts for a wide range of industries. Their development services include layup design, material selection, mechanical simulation, prototype manufacturing, dimensional and mechanical testing.

Depending on requirements, Ensinger develop new manufacturing processes and their automation.

Their process portfolio allows for the manufacture of stock shapes, moulded blanks for further machining, net shape parts and lightweight structures.

Contact Supply Services Limited today to discuss your application requirements

We have invested both time and money to train and certify our staff so they can provide you with accurate material selection services. It’s important that the person you are talking to has the knowledge to select the correct engineering plastic material to suit your application.

Our staff are IAPD (International Association of Plastic Distribution) trained and certified so you can be sure that you are talking to an expert.

Is your current engineering plastic supplier at this level of knowledge across the entire material range or are they just selling you another chunk of plastic hoping it will do the job? Don’t leave your business reputation or a critical component to chance, talk to our experts so you have confidence in your purchase.

Call one of our branches direct or make a toll-free call by contacting us via 0800 102 112

Our team looks forward to being of service…it’s in our name!