Thermoplastics Engineering

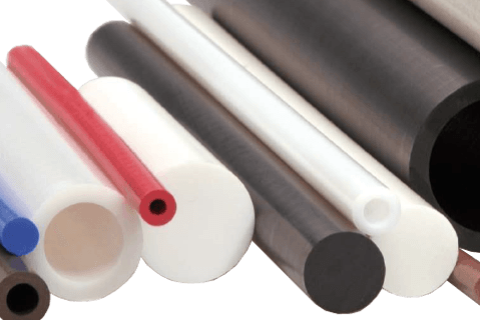

As one of the leading engineering thermoplastics suppliers in NZ of rod tube sheet, we know it takes a lot of engineering thermoplastic products and industrial composites to keep New Zealand industry moving.

Since 1980 our comprehensive selection of premium engineering thermoplastic materials and industrial composites have been widely utilised across New Zealand industry.

From bottle filling plants to bridge building, underground mining to outer space.

Our materials keep things moving.

We are proud of our long-term associations with the leaders in engineering thermoplastics, high performance plastics and composites. These companies are recognised as some of the leaders in this market space.

Ensinger Plastics Our partner and market leader for high performance plastics

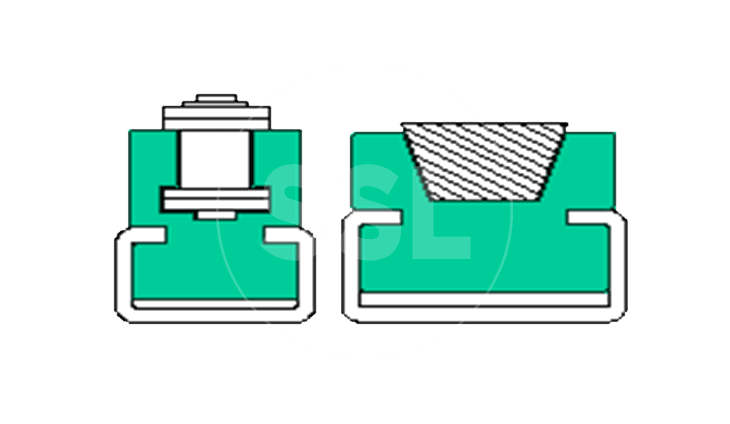

TriStar Plastics Leaders in polymers, industrial composites and self-lubricating bearings

Polymer Industries World leader in polyolefins manufacturing

ACM Composite Bearings Leaders in composite bearings and resin bonded materials

Gaurniflon S.p.A Worldwide leaders in PTFE compounds

Norplex Micarta North America’s leading producers of thermoset composites

Northern Plastics Specialists in UHMWPE extrusions and polyurethane castings

Okulen Engineering Plastics High performance polymer production and processing

We have invested both time and money to train and certify our staff so they can provide you with accurate material selection services. It’s important that the person you are talking to has the knowledge to select the correct engineering plastic material to suit your application.

Our staff are IAPD trained and certified so you can be sure that you are talking to an expert.

Is your current engineering plastic supplier at this level of knowledge across the entire material range or are they just selling you another chunk of plastic hoping it will do the job? Don’t leave your business reputation or a critical component to chance, talk to our experts so you have confidence in your purchase.

With our unrivaled range stocked right here on the shelf in New Zealand and our access to materials from quality manufacturers, we can offer your business more than just plastic. We can provide your staff with our expertise in material selection, cut to size services, CAD design and our end to end nationwide manual and CNC machining services.

We have access to some of the most knowledgeable international experts that help us when you come to us with something new or bleeding-edge.

On a daily basis we take your ideas and turn them into reality. This is how we keep New Zealand industry moving.

Since 1980 we have built an enviable reputation for our quality products and our exceptional customer service. We care about getting things right the first time and looking after our customers.

This level of service has seen us evolve from a small town business to a major nationwide player with branches located in Auckland, Mount Maunganui and Christchurch.

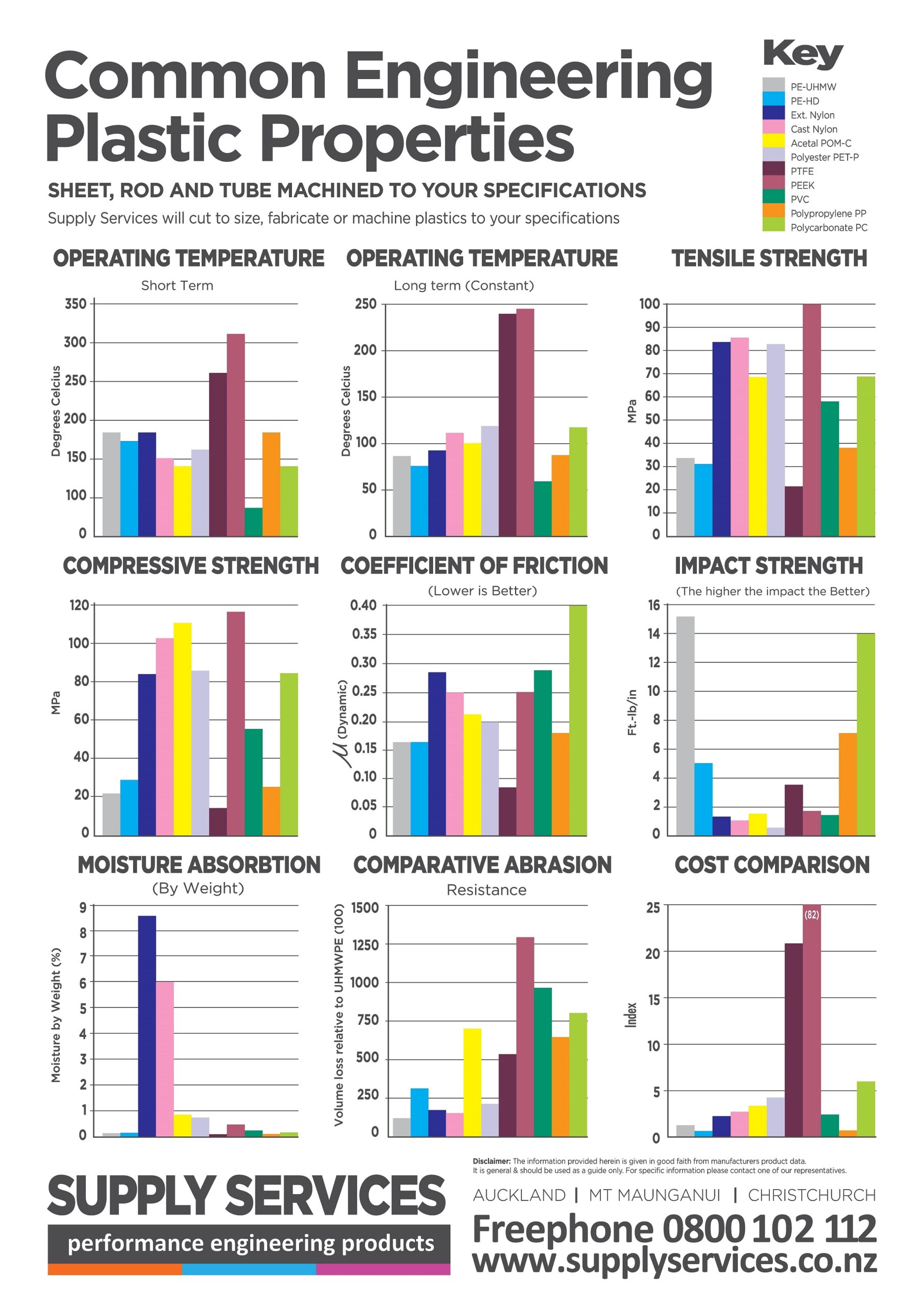

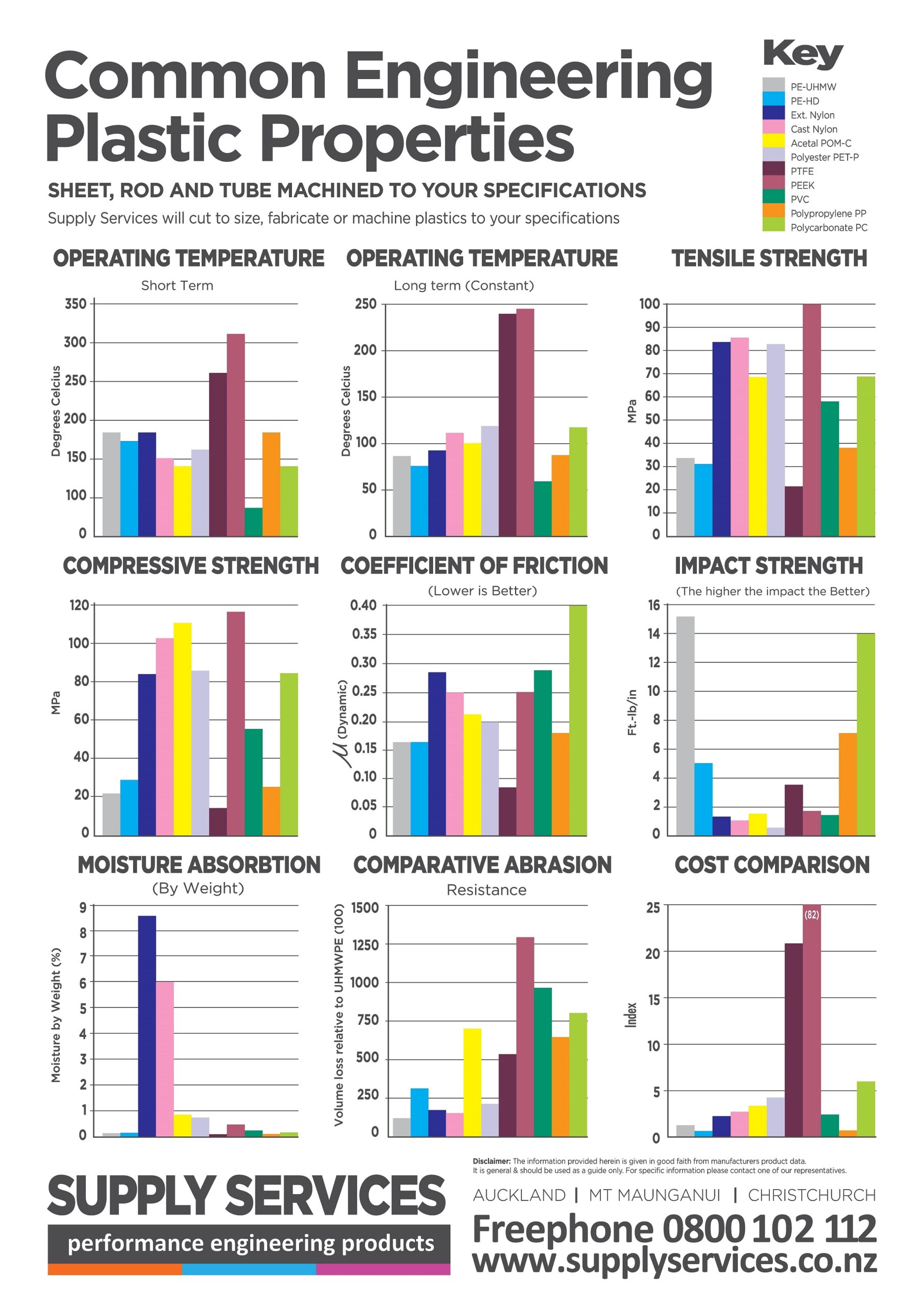

Our engineering plastics properties chart for engineers has been widely distributed over the years. A simple, easy to understand visual reference point.

Our chart covers materials such as UHMWPE, HDPE, Cast Nylon, Extruded Nylon, Nylon 6, Nylon 66, Acetal POM-C, Polyester PETP, PTFE Teflon, PEEK, PVC, Polypropylene PP and Polycarbonate PC.

With such a large stock holding of engineering plastics, engineering plastic products and industrial composites, we have broken our range of materials into the following categories.

High Performance Plastic Materials

Our premium range of high performance amorphous or semi-crystalline thermoplastics and imidised materials are capable of long-term thermal stability up to 260°C. Some to 300°C with short term bursts up to 400°C.

Our selection includes PTFE, PEEK, PVDF, PSU, PPSU, PEI, PPS, PBI, PAI, and PI materials from leading international manufacturers. These materials generally offer the highest strength and stiffness, plus water, steam and chemical resistance.

All materials are available in a range of modified grades.

Have a read how medical grade TECASON P MT is used for knee replacement trials.

Engineering Plastic Materials

Our range of amorphous or semi-crystalline engineering thermoplastics are generally suitable for applications up to 120°C. Engineering plastic products tend to be of medium cost, with moderate temperature resistance, mid-range strength, and exhibit good impact and chemical resistance.

Our selection encompasses cast and extruded Nylons PA6 and PA66, Acetal POM, PBT, PET and Polycarbonates. Additionally, modified grades of all engineering plastics products are available.

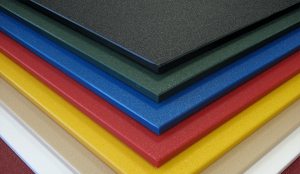

Standard Plastic Materials

Our range of standard plastic materials are referred to as commodity plastics. These materials are either amorphous or semi-crystalline thermoplastics which are generally low cost, have low temperature resistance, low strength, but are widely used across many New Zealand industries in applications up to 90°C.

Our range encompasses different thicknesses and colours of UHMWPE, HMWPE, HDPE, LDPE, PVC, ABS, PPE, Acrylic, Polyurethane and Polypropylene.

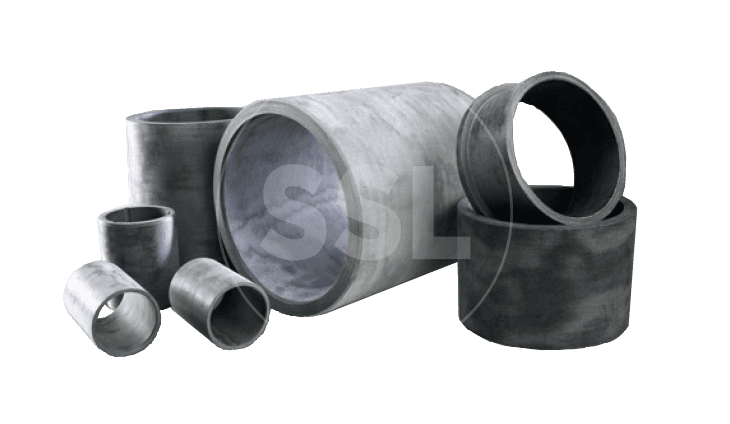

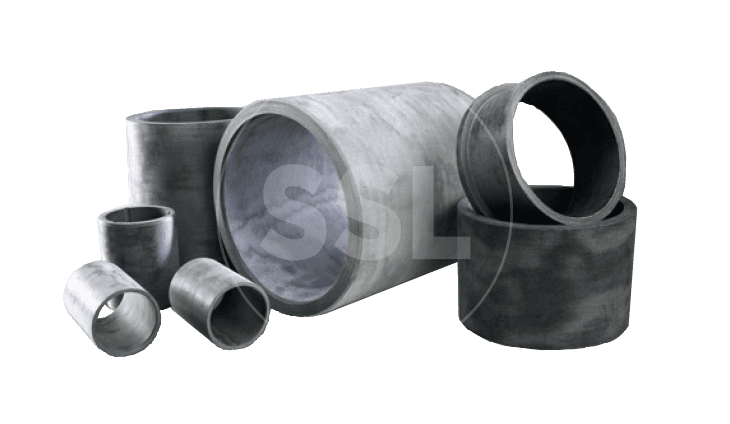

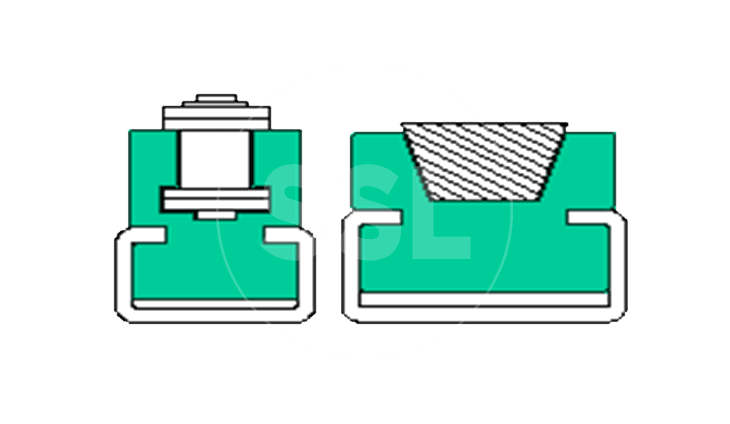

Composite and Laminate Materials

Manufactured from various base resins such as phenolic, epoxy, melamine, silicone and polyester. Then combined with various layers of reinforcing using paper, cotton, glass matting or other high performance fabrics incorporating carbon fiber or Kevlar, they create a diverse range of materials to suit many industrial applications.

From electrical switchboards to ocean-going ships’ stern tube and rudder bearings, we have the composite to keep your operation moving. Available in rod tube sheet.

Specialty Materials

Specialty materials are generally intended for a specific purpose and may come with a particular surface finish or an internal modification. We stock a large range of these materials and can also machine them to your requirements.

Applications for specialty materials cover food cutting boards, play grounds, pleasure boat parts, signage boards, privacy partitions, light-weight panels for automotive, skate board ramps and much more! Please contact us for further technical information and availability.

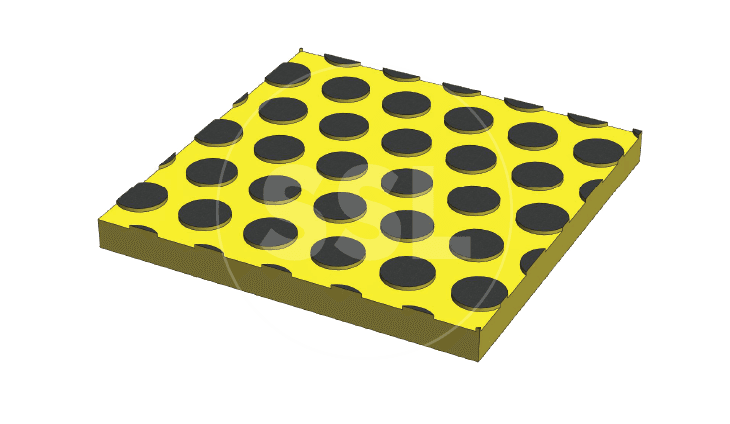

Non-Skid or Anti-Skid Products

Non-skid or anti-skid sheeting products make slippery areas safer. Our range of non-skid sheeting suits heavy-duty applications where machinery needs traction, and where corrosion and chemicals may limit the effectiveness or life of other non-skid products.

Typical application sectors include the military, oil & gas, diving platforms, marina’s and pleasure boats. If it needs to be tough, we have products to suit.

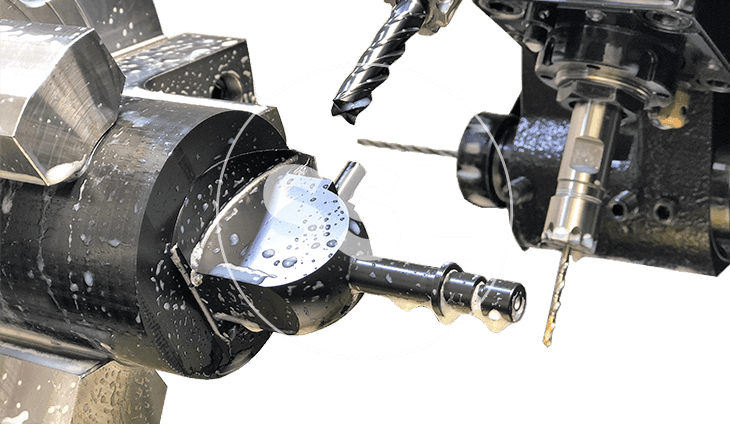

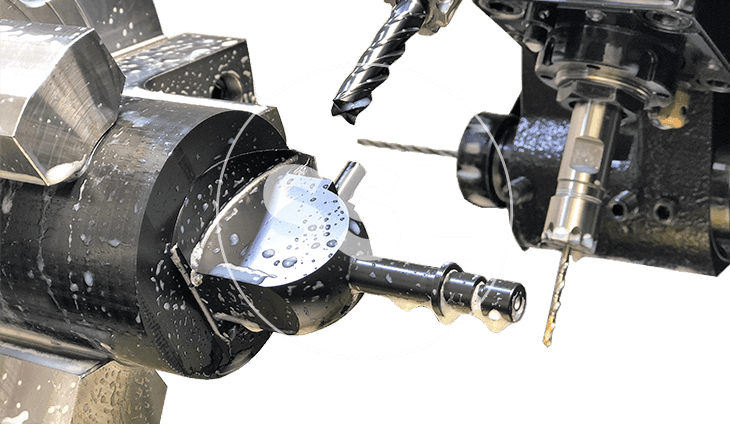

All three of our nationwide branches offer CAD design, manual and CNC machining services; all are fully stocked with engineering plastics, chains, sprockets and associated parts. No matter where you are in the country, we have the people and the know-how to help you out.

Our services include:

- Computer Aided Design (CAD)

- CNC turning (2 & 4 Axis)

- CNC milling (3 & 4 Axis)

- CNC routering (3 & 5 Axis)

- Conventional turning & milling

- CNC billet cutting

- Production keying

- Thicknessing

- Custom profiles

- Cut to size rod, tube & sheet

- Plastic fabrication

- Plastic & metal welding

- Magnetic particle inspection NDT

- Portable CMM inspection system (probe & laser)

Check out our full range of engineering services on offer

Get your engineering plastics Auckland at Unit 23, 761 Great South Road, Penrose, Auckland. Get your engineering plastics Tauranga at 67 Newton St, Mount Maunganui. Get your engineering plastics Christchurch at 11 Dakota Crescent, Sockburn, Christchurch. One nationwide toll free number.

Whatever your’re engineering, we can help. Nationwide freephone 0800 102 112

Engineering plastics being CNC machined into finished parts

Return to our home page or if you would like to know more about Supply Services go to our company page.