Marine Bearings and Bushing Materials

Supply Services Limited stocks a range of marine bearing and bushing materials across our network of three New Zealand branches. Able to be run in wet or dry applications, our materials are the perfect replacement for bronze. Resistant to saltwater, chemicals, and corrosion; they offer outstanding wear life and performance.

Commonly used for marine applications such as rudder or stern tube bearings, stave bearings, winch bushes, door and hatch cover bushes, and a range of associated deck equipment. We offer inhouse CAD design and CNC machining services to turn our range of marine composites and polymer plastics into your finished marine bearing or bush.

Eliminate external lubrication

Eliminating external lubrication is one of the key choices in material selection. Our marine bearings and bushings have internal lubricants that are evenly dispersed throughout the composite or polymer material to ensure lubrication is maintained throughout the parts life cycle. Due to the already inherent low coefficient of friction, external lubrication can usually be designed out of the solution. Eliminating the use of lubricants can be achieved by using our ACM Composites or Ensinger TECAPET polymer plastic range of materials.

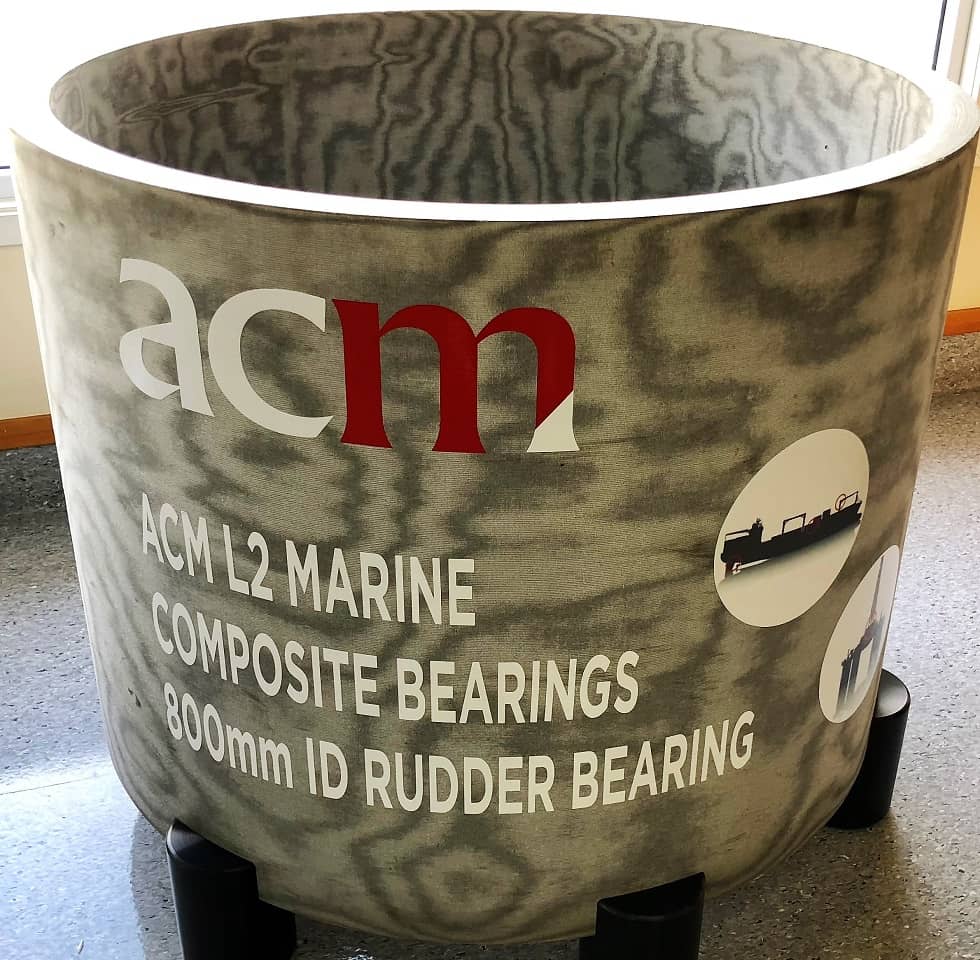

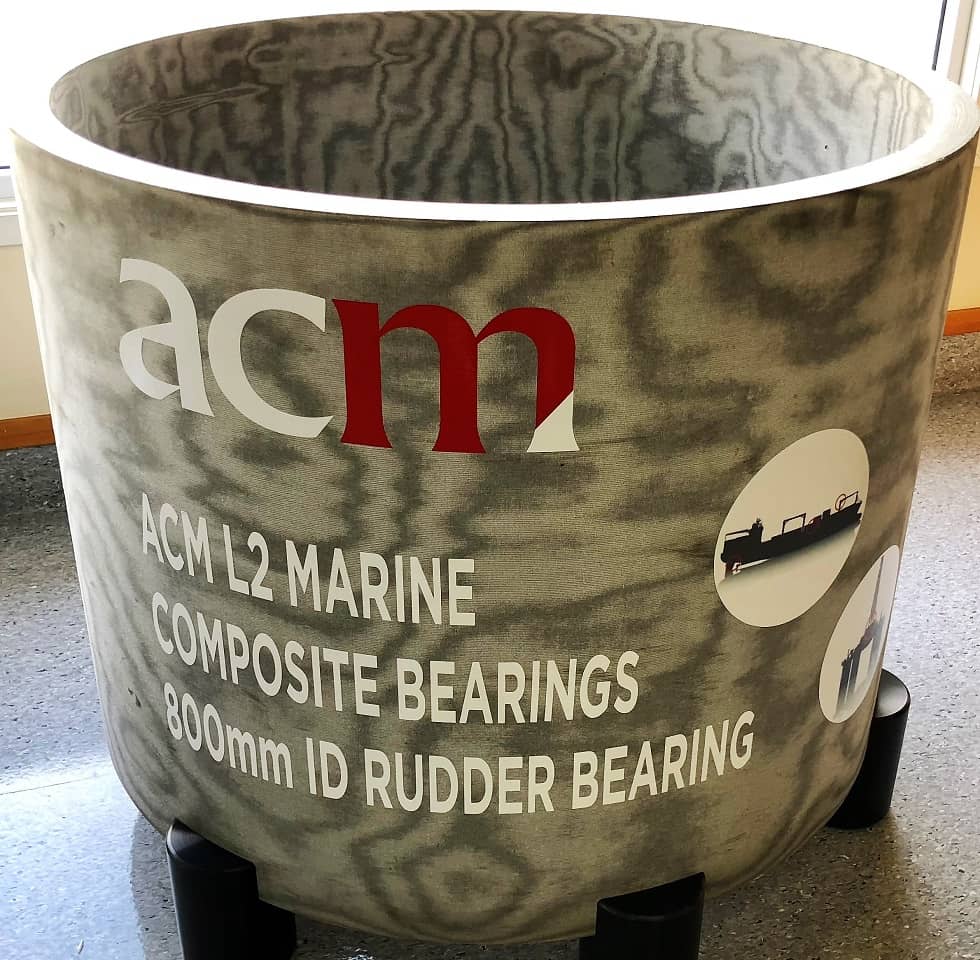

Composites for marine bearings and bushes

We stock quality, field-proven, ACM Composite bearing materials in New Zealand. Tribotex 7 (natural unlubricated) Tribotex7G (Graphite filled) and ACM L2 marine (PTFE & Molybdenum Disulphide filled). L2 Marine is our primary marine grade and is a high load composite bearing material that has been specifically formulated for marine environment applications. It comprises synthetic fabric reinforcement impregnated with a thermosetting resin and solid lubricant fillers.

L2 Marine is the only composite material approved to operate as a rudder bearing in wet and dry conditions at bearing pressures up to 10 MPa. Class approvals are held from many of the world’s foremost classification societies. L2 Marine has been tested and approved for stern tube bearing applications and has been proven to offer superior performance in terms of wear, extended life and low shaft wear over other water lubricated propeller shaft bearing materials. It is for these reasons that many navies use ACM material for their stern shaft bearings.

Commonly used in larger vessels as stern tube bearings, rudder bearings, stave bearings, davit crane bushes, fairlead bushes, winch bushes and other associated deck equipment. Our composite range will not corrode or swell in salt water, these composites can handle very high loads and moderate shaft misalignment. Coefficient of friction is low, with low thermal expansion rates. The lubricants are built into the material matrix meaning shafts are lubricated.

PET (polyethylene terephthalate) for marine bearings and bushes

High-performance Ensinger Plastics, TECAPET PET materials are available in natural grade, additionally TECAPET TF with a solid PTFE lubricant. Offering very good abrasive resistance and wear characteristics, TECAPET PET is often used in smaller pleasure craft as sheaves, rudder bearings, stern tube bearings, winch bushes, door and hatch cover bushes. TECAPET TF with solid lubricant offers lower frictional properties. TECAPET will not corrode or swell in salt water, it can handle moderate to high loads.

The lubricants are evenly dispersed throughout the material, constant lubrication will be maintained throughout the life cycle. Due to its good creep strength, low moisture absorption and outstanding dimensional stability, engineering grade PET is extremely well suited for applications where complex parts and the highest requirements regarding dimensional accuracy and surface quality are needed. This bearing and bush material is so tough that it helped slide a massive bridge over the Kawerau Gorge, south of Queenstown.

Did you know?

Supply Services stocks Torlon balls for the New Zealand marine industry. Torlon with a chemical name of polyamide-imide, is commonly referred to as PAI. Torlon/PAI is a far superior product than stainless steel ball bearings. Click the button below to read more about the advantages of Torlon balls for the marine industry.

internalCall our team today!

Every day we help people around New Zealand make better marine bearings and bushings with our high-quality range of composites and polymer plastics from leading international suppliers.

We offer material identification and selection services, cut to size plastics and a full range of CAD design and CNC machining services.

Click the links below for the contact details of your closest branch.