PET TF (PET + PTFE)

Availability

6mm to 160mm OD

N/A

8mm to 100mm Thick

Light Grey

No

Yes, however some sizes have minimum order quantity

Features

TECAPET TF is used widely within the mechanical engineering, food technology, electronics and automotive sectors. With its high abrasion resistance, excellent sliding properties, strength & low moisture absorption, it is the material of choice for many engineers.

Just like our TECAPET PET standard material, TECAPET TF (PET + PTFE) is food contact approved and has both FDA & EU 10/2011 compliance. TECAPET TF is widely used in the food processing & food technology sectors within New Zealand as an un-lubricated bearing material.

The perfect material for mating soft steels and plastic surfaces. Often used for sliding applications such as slide ways, bearings with high load, un-lubricated parts, gears & thrust washers. TECAPET TF can outperform oil filled nylons and lubricated Acetal POM materials in certain applications.

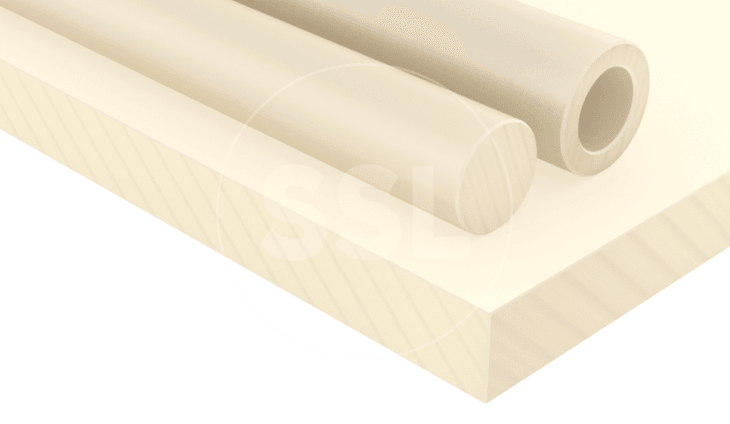

PET PTFE Blend Range

| Product Type | Industry Usage | Available Products & Notes *Some items are manufactured & imported on request |

|---|---|---|

| TECAPET TF Grey | Mechanical Engineering, Food Industry, Electronics, Automotive Technologies | Rod & Sheet Light Grey FDA and EU 10/2011 approvals generally available. Verification before purchase is recommended. |

Suppliers

Related Products / Services

Whatever you’re

engineering, we can help