Nylon Plastics

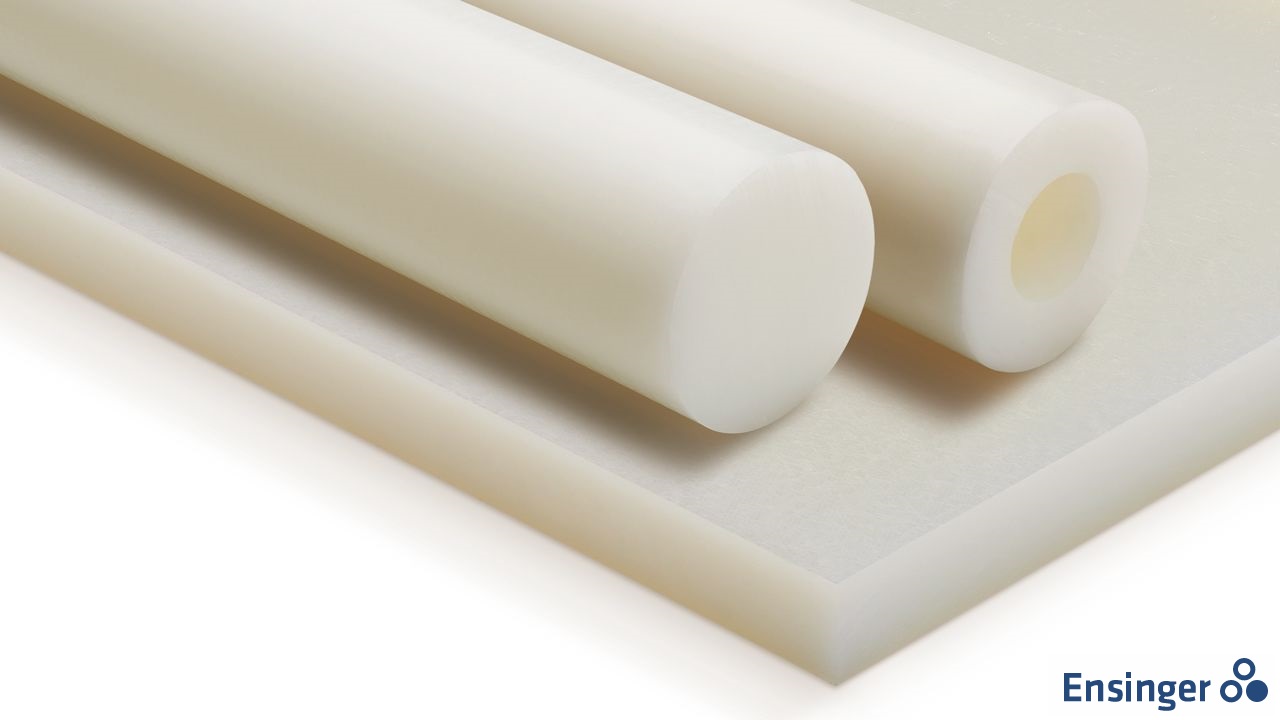

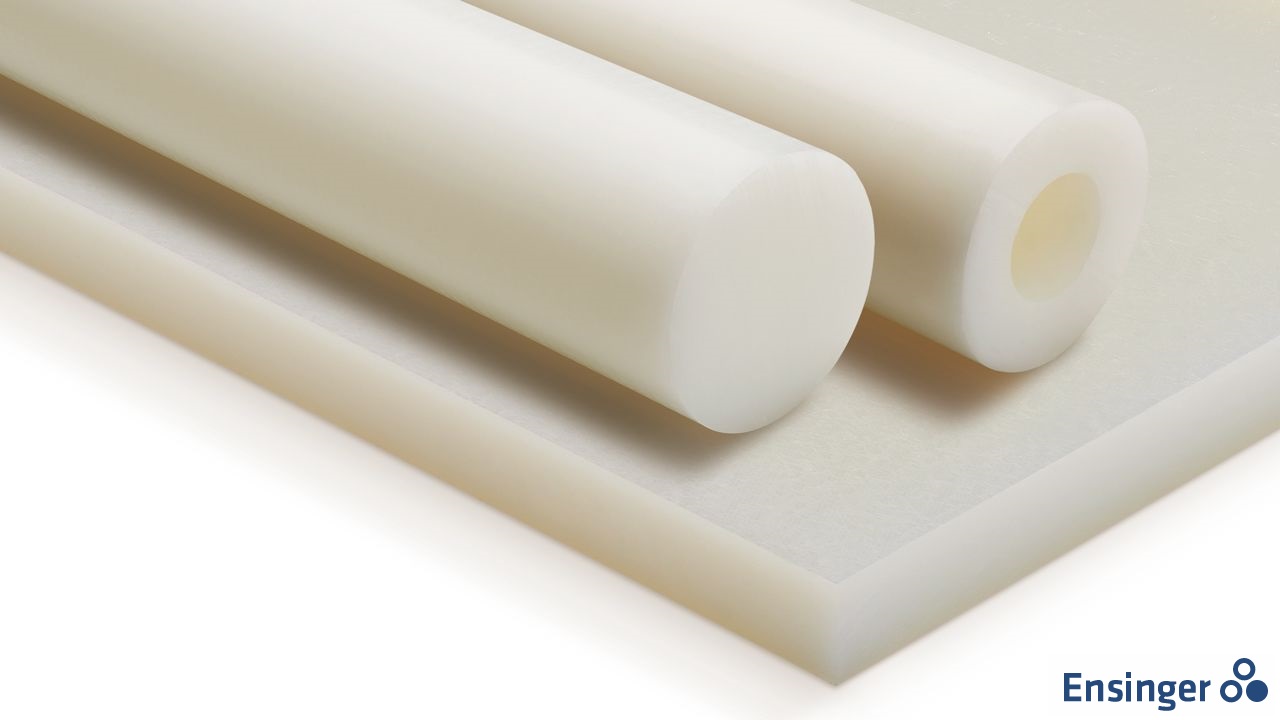

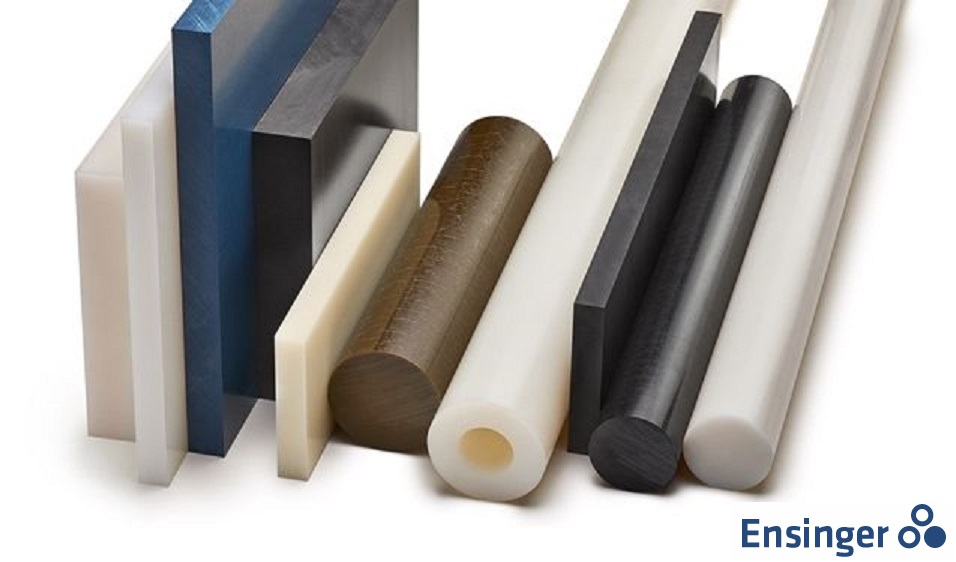

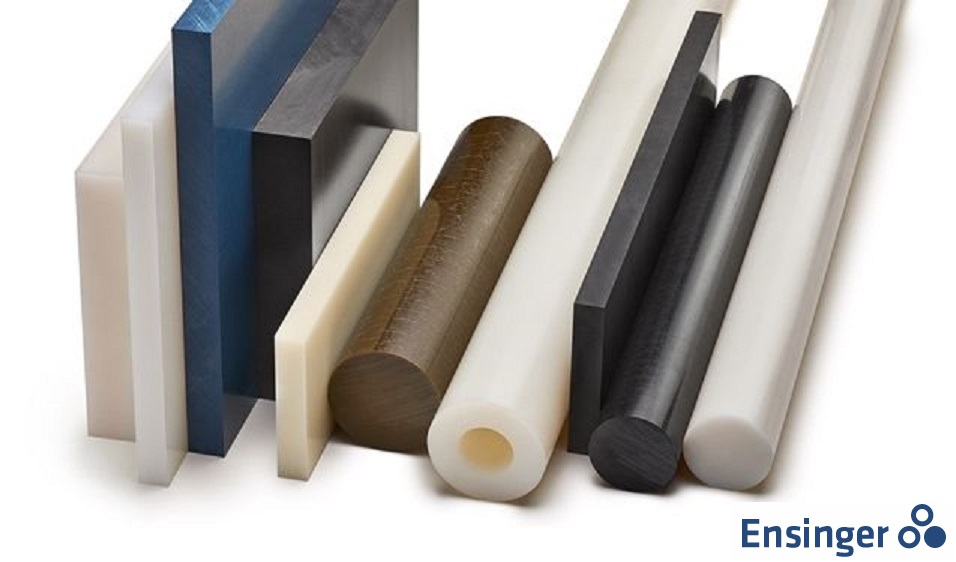

Our range of Nylon plastics for engineers is available in rod, tube and sheet in grades PA6, PA66 and PA12. Standard and enhanced grades available.

Need cut to size Nylon engineering plastic materials today or tomorrow?

Call us now! Nationwide toll free 0800 102 112.

Table of contents

- What stock sizes of Nylon rod, Nylon tube and Nylon sheet are available?

- What are Nylon thermoplastics?

- What are the key characteristics of Nylons for engineering?

- What do the numbers mean such as Nylon 6, Nylon 66 or Nylon 12?

- Should I use Nylon PA6, Nylon PA66 or PA12?

- Extruded or cast Nylon?

- What modified grades of Ensinger Nylon plastics are available from Supply Services?

- Modified Extruded Nylons

- Modified Cast Nylons

- What is the service temperature range of Nylon?

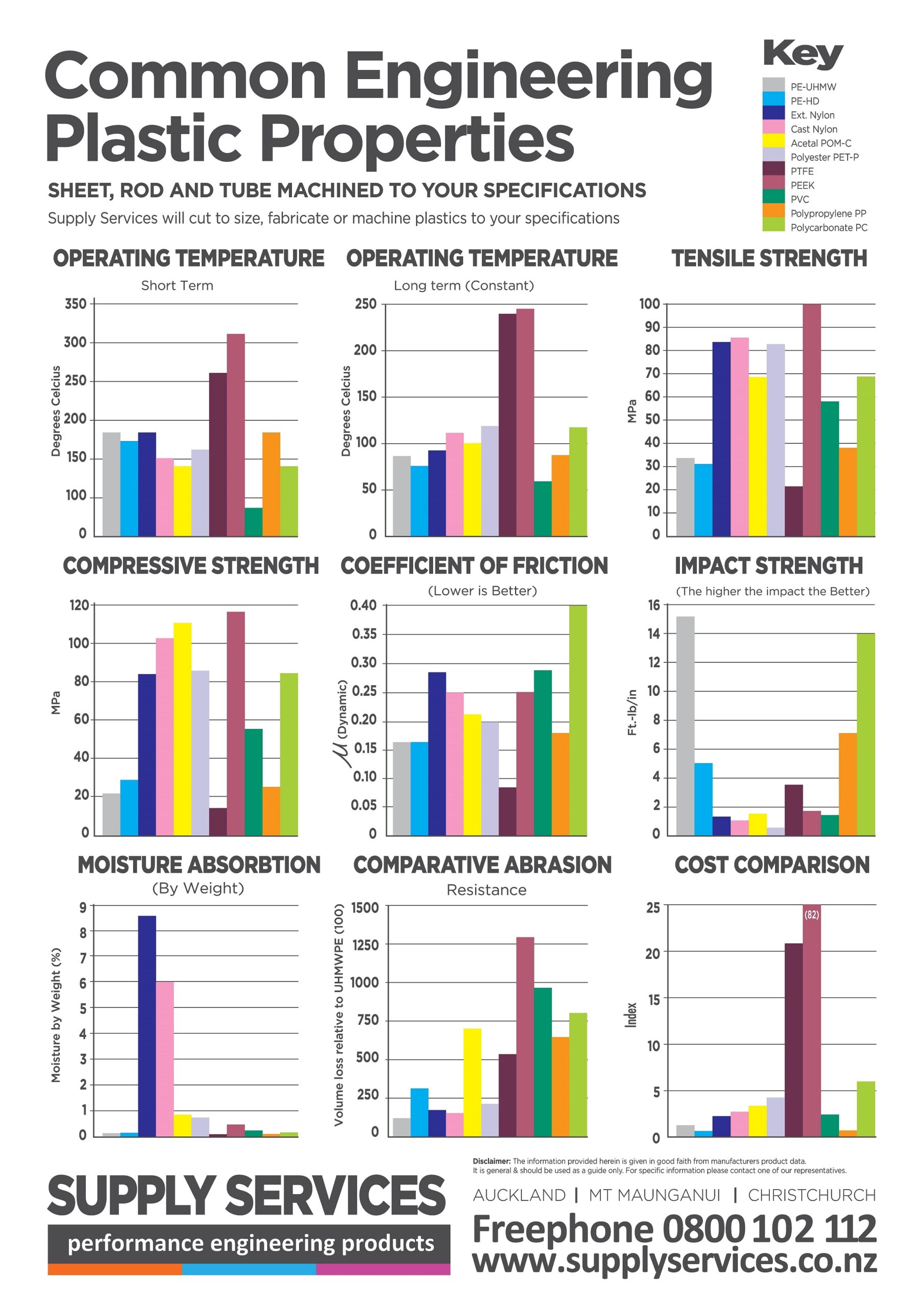

- Download our visual and hugely popular Plastics Properties Chart

- What is the melting point of Nylon?

- Does Nylon plastic absorb moisture?

- Are there food grade Nylons?

- What are Nylon engineering plastics commonly used for?

- What are common brand names for Nylon engineering plastics out in the field?

- Download our Engineering Plastics brochure

- Want to know more about our range?

What stock sizes of Nylon rod, Nylon tube and Nylon sheet are available?

We hold a large range of Ensinger Nylon plastics in stock, but due to the number of grades available we cannot hold them all. Call our team on 0800 102 112 to confirm your requirements.

Stock shapes available from the entire range are:

Extruded Nylon rod from 4mm to 250mm diameter and in cast from 50mm to 800mm diameter.

Extruded Nylon tubes from 25mm to 300mm outside diameter (OD) with numerous inside diameters (ID). Cast from 50mm OD to 600mm OD, again with various IDs.

Extruded Nylon sheet from 5mm thick to 100mm thick and cast from 8mm thick to 200mm thick.

What are Nylon thermoplastics?

Nylon is from the family of polymers called polyamides and is often referred to and abbreviated as PA.

Nylon PA is a man-made semi-crystalline thermoplastic.

Able to be melt-processed, Nylon can be used to manufacture items such as fibres, films and moulded objects.

Nylon materials are tough and lightweight.

Nylon was one of the first commercially successful thermoplastics invented, by DuPont in 1935.

By 1940 commercially available products hit the stores as toothbrushes and women’s pantyhose.

Likely to be the most widely used engineering plastic today, Nylon is seen in the automotive industry, in business machines, home appliances and industrial equipment.

Common grades that this article will mention are Nylon 6, Nylon 66 and Nylon 12.

Other grades are available such as Nylon 46 and Nylon 11.

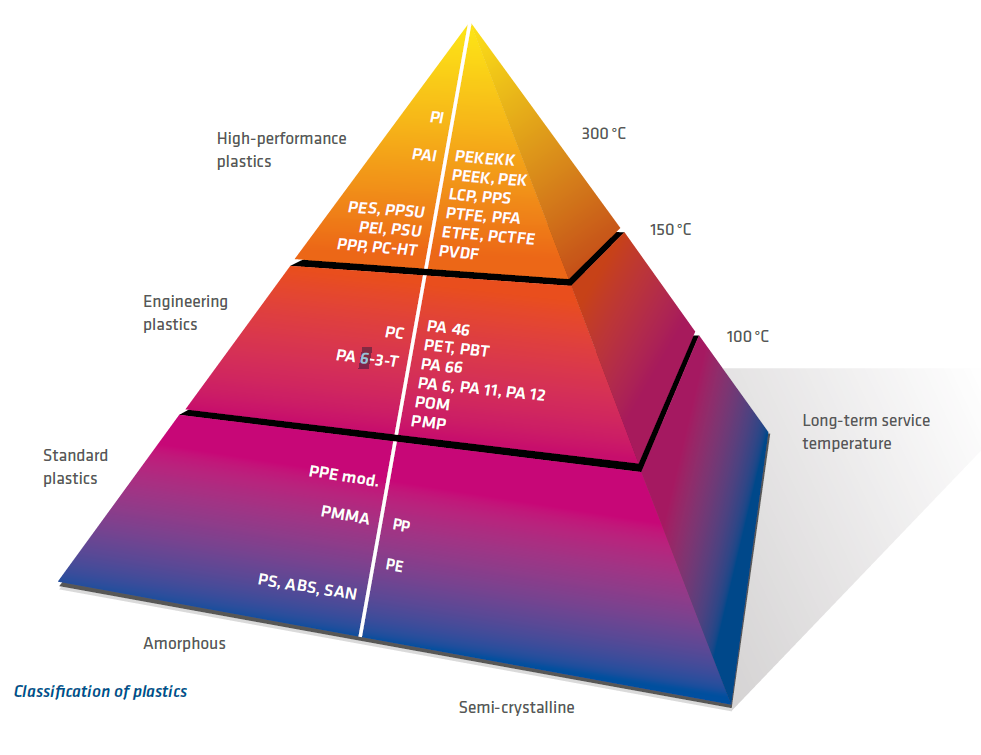

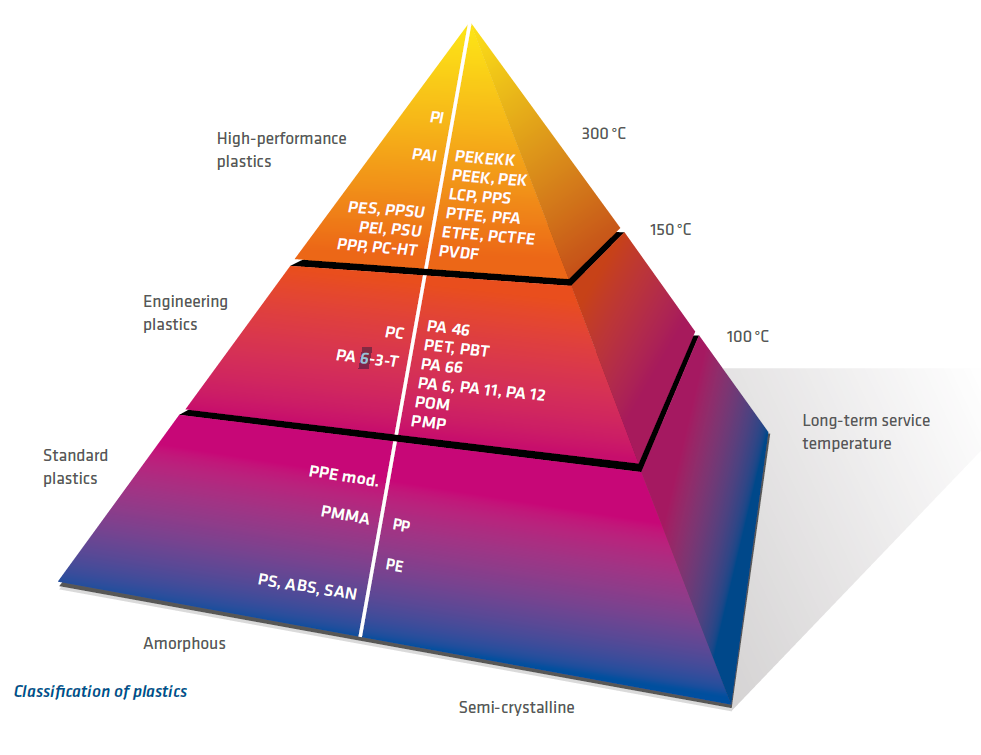

The below graphic of the plastic classification pyramid shows Nylon PA materials sitting mid-range on the semi-crystalline side (slide and photos courtesy of Ensinger Plastics).

What are the key characteristics of Nylons for engineering?

Nylon plastic for engineering tends to be very tough and hard wearing.

It offers high impact resistance, moderate strength, a low coefficient of friction and a good degree of bearing and wear properties.

Chemical and temperature resistance, plus mechanical damping are three more notable features of Nylon.

All these characteristics and features make Nylon a versatile material at a mid-range price point.

Nylon absorbs a high percentage of moisture compared to other engineering plastics and this must be taken into account if dimensional stability of parts are required.

Different grades of Nylon absorb varying percentages of moisture, so it is best to check with us to confirm the grade selected is up to the task.

Being a semi-crystalline thermoplastic, general key characteristics are: sharp melting point, tend to be opaque, are difficult to bond, have good fatigue resistance and are great materials for bearing, wear and structural applications.

What do the numbers mean such as Nylon 6, Nylon 66 or Nylon 12?

These Nylon plastic polymers are all from the same family but each has a different chemical structure or molecular chain.

The number refers to the count of carbon atoms in the chain.

Common examples are Nylon PA6, PA46, PA66, PA12.

Nylon PA6 for example has 6 carbon atoms and 1 monomer. Nylon PA66 has 2 monomers with each having 6 atoms.

Should I use Nylon PA6, Nylon PA66 or PA12?

For a large amount of applications it might not even matter if the wrong material was selected (you might be paying to much though!).

But under certain operating conditions or industry applications you need to make sure you do have the correct Nylon plastic to avoid breakages, accidents or downtime.

Our range of Nylons are from Ensinger Plastics. Ensinger produces high quality semi-finished stock shapes from over 100 different plastics to suit a vast array of industry applications.

We are proud to represent Ensinger materials in New Zealand.

TECAMID 6 – Nylon PA6E Extruded

Our TECAMID PA6 Nylon provides good damping capacity, good impact strength and a high degree of toughness even at low temperatures.

Good wear resistance, especially against rough surfaces finishes.

Good overall resistance to chemicals. Natural in colour.

TECAMID 66 – Nylon PA66E Extruded

Our TECAMID PA66 has good rigidity, hardness, abrasion resistance and thermal dimensional stability.

It has better machinability than TECAMID 6 and is particularly suitable for parts which are subjected to high mechanical and thermal loads.

Natural in colour.

TECAST T – Nylon PA6C Cast

Compared to TECAMID PA6, cast Nylon has better physical properties such as higher tensile strength, maximum stiffness and hardness, better wear resistance, lower moisture absorption and better dimensional stability.

It particularly suits the production of large parts and thick wall sections.

Available in natural and colours.

Extruded or cast Nylon?

There is a difference between the shapes produced by extruding or produced by casting. Extrusion normally creates small, larger production runs of parts.

Casting normally creates larger but lower internal stressed parts.

Both extruded and cast Nylon plastics can be modified with fillers or lubricants to enhance the base proprieties of the Nylon plastic.

What modified grades of Ensinger Nylon plastics are available from Supply Services?

Supply Services stocks a range of modified Nylon engineering plastics from Ensinger. The range of materials is vast.

We stock on the shelf in NZ the most popular materials that engineers require to keep NZ industry moving.

Our scope of modified materials covers both extruded and cast Nylons.

Modified Extruded Nylons

TECAMID Nylon PA6 MO Black

With the addition of molybdenum disulphide (MoS2) which improves sliding and frictional properties. Impact strength is reduced however. Offers improved UV resistance.

TECAMID Nylon PA6 GF30

Filled with 30% glass fibres to increase the mechanical properties such as higher strength, rigidity, creep strength and dimensional stability. Less suitable for sliding applications.

TECAMID Nylon PA66 MO Black

This material offers a higher long-term service temperature of 110ºC (10ºC higher) when compared to its PA6 counterpart.

TECAMID Nylon PA66 GF30

This material also offers a 10ºC higher service temperature than PA6 GF30.

In the extruded range, we are also able to supply 35% glass filled Nylons, flame resistant Nylons, carbon fibre reinforced Nylons, heat stabilised Nylons, solid lubricant filled nylons and Nylons with metal fillers for metal detection equipment used in the food industry.

Modified Cast Nylons

TECAST T MO

Similar to standard cast PA6C but with added solid lubricant molybdenum disulfide. Good UV resistance and improved sliding properties.

High surface hardness, high strength, good damping properties.

Tough material providing high abrasion resistance. Machines well.

TECAST L YELLOW

Nylon oil is a lubricant modified cast PA6C which is particularly suitable for applications involving dry running.

The uniform distribution of lubricant over the whole cross-section achieved with NYLON OIL guarantees a constant sliding and wear behaviour throughout the whole service life.

We can also supply cast Nylons in blue colour for visual identification, Nylons with the addition of a proprietary solid lubricant and Nylons that have 15% elastomer added.

What is the service temperature range of Nylon?

Our range of Nylon plastics generally have a constant service operating temperature of 100ºC with some of the modified grades able to work at 110ºC.

Short term, our Nylons can handle around 160ºC with some grades able to peak to 170ºC.

Depending on your application, it is always wise to check with our team to make sure that the material you have selected fits within its operational parameters.

Ensinger definitions of short term and long term temperature resistance for plastics is as follows:

The short-term service temperatures are the short term peak temperature values that the plastic can withstand for a period of minutes or sometimes even hours without the plastic being damaged, taking into account the load and its duration.

The long term service temperature is defined as being the maximum temperature at which plastics can be kept in hot air for 10,000 and 20,000 hours without losing more than 50% of the initial values for their typical properties.

Our experience shows that most standard or engineering class plastics if heated up slowly to the maximum short term temp would have lost a lot of their mechanical strength.

This is important information to know and you may need to jump to a higher performance material.

Download our visual and hugely popular Plastics Properties Chart

What is the melting point of Nylon?

Anywhere from around 210ºC to 260ºC dependent on the grade of Nylon plastic.

Does Nylon plastic absorb moisture?

Of all the standard, engineering and high performance plastic materials we distribute, Nylon is by far the one that absorbs the most amount of moisture.

Extruded Nylons take on much more moisture than their cast Nylon counterparts. For example cast Nylon PA12 absorbs 1% at saturation, compared to 5-7% for Nylon PA6.

Nylon doesn’t have to be submerged to take on moisture, it absorbs it directly from the air.

This moisture affects the dimensions of machined parts and also reduces Nylons strength and stiffness, but does increase its toughness.

Are there food grade Nylons?

Yes, and we stock a wide range of FDA and/or EU10/2011 compliant Nylon plastic materials right here in NZ.

Supply Services can provide food conformance certification from Ensigner.

This must be requested at time of order. Not all suppliers can offer certification of their materials.

If certification is important for your finished machined parts, please make sure you let our staff know.

We cannot issue certification once materials have left our warehouse or control.

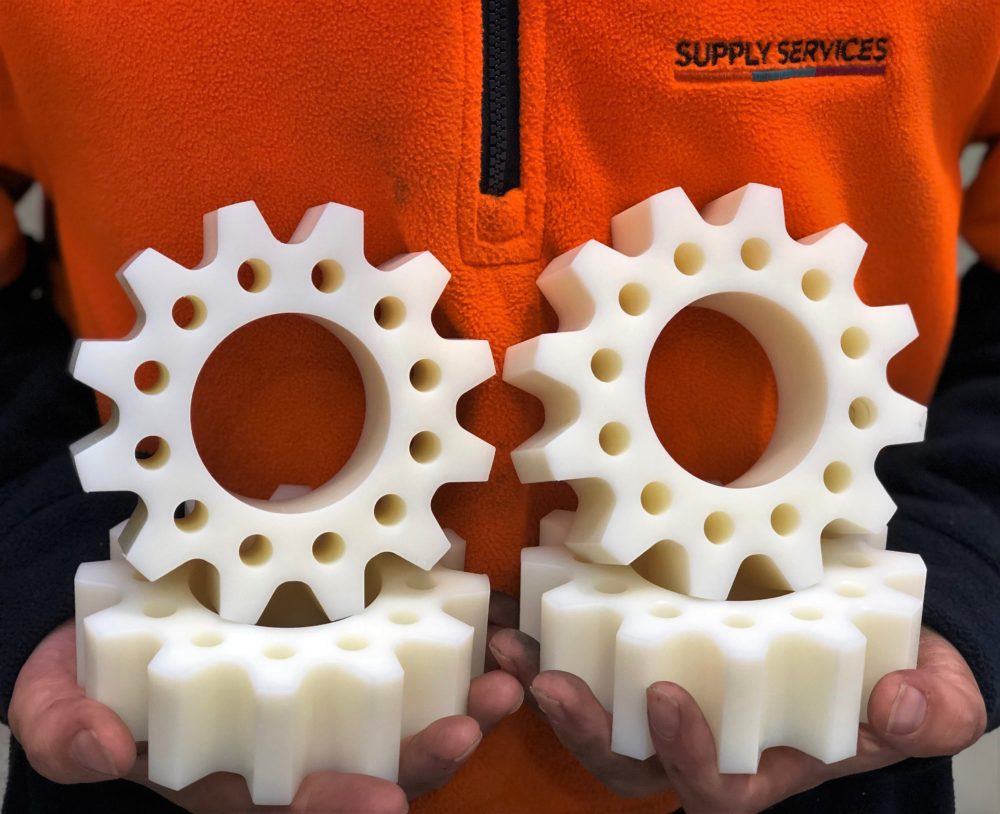

What are Nylon engineering plastics commonly used for?

Applications that engineering Nylons can be used for are virtually limitless.

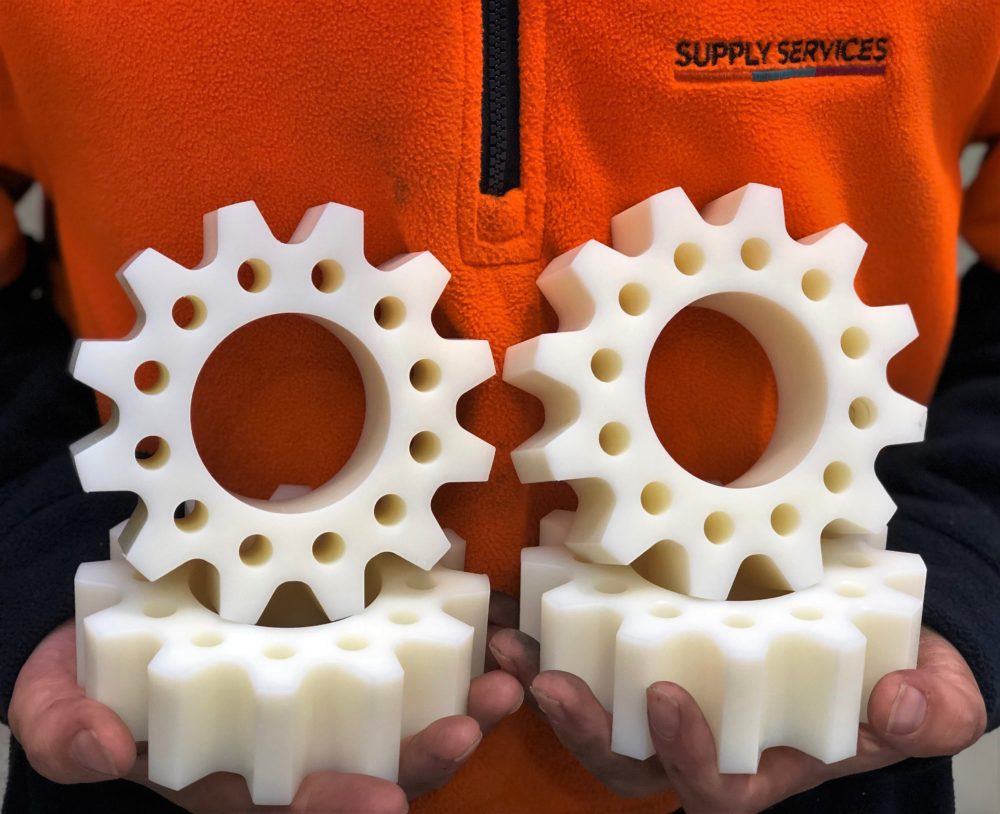

The most common applications we see that engineers use nylons for are: gears, rollers, sprockets, bearings, rollers, bushings, cable sheaves, wear pads and wear strips, structural parts, chain guides, wheels, thrust washers, parts requiring impact resistance, mechanical damping or applications requiring food grade materials.

What are common brand names for Nylon engineering plastics out in the field?

Polyamide, TECAMID, TECAST, Northex, Nylatron, Nylatron GSM, Ertalon, Ertalon LFX, Vekton, Nycast, Oilamid, Sustamid, Zellamid, Nylatech, Ensilon, Tuffkast, Nyoil, Celanese, HYD, Hydlar, MC901, MC907, Monocast, Stanyl, Ultramid and Zytel.

Want to know more about our range?

Read a recent blog post about our premium engineering thermoplastic materials and industrial composites or specifically about our UHMWPE polyethylene products.

Looking for information about machining engineering plastics? Check this out.

Contact us today to discuss your requirements and let our experienced team advise you of the best material to suit your application.

We look forward to being of service to you and your business.

Read more about Supply Services Limited or return to our Home Page.

Should you find the information in this post beneficial, we would appreciate if you shared this blog post with your team, on your website or social media channels.

Be social and share the knowledge.