Conveyor Chain Sprockets

Availability

5-25 or custom

Low, std & high profile

A, B or C

50mm to 250mm or custom

Custom to your tolerance

Metric & imperial

Features

A range of materials are available to suit the conveyor chain sprockets application. Mild steel, Hardox 400, induction hardened C1045 , stainless steel, polyurethane, nylons, UHMWPE, acetals and composites.

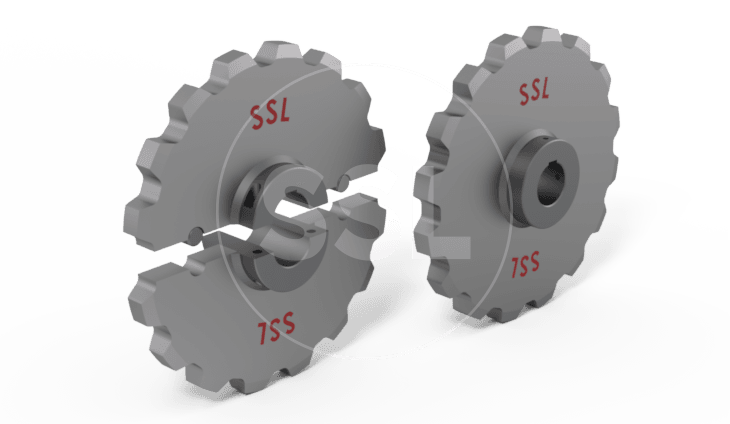

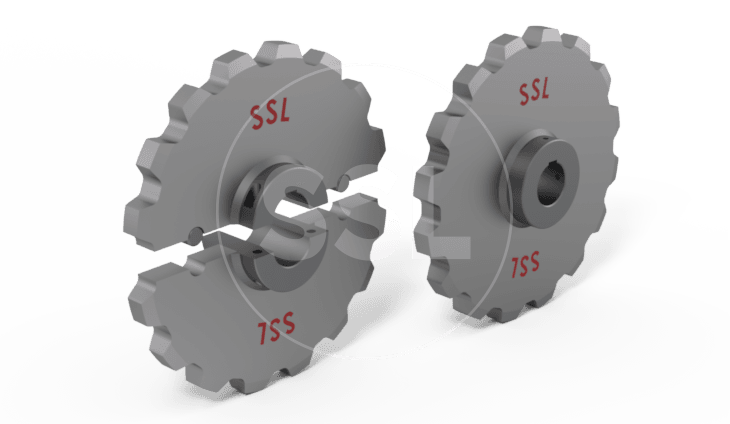

Want to make sprocket & shaft assembly simpler? Split sprockets provide an economical means of mounting sprockets on shafts where it is prohibitive to dismount the shaft assembly. Choose from split for welding or split for bolting.

Want to be able to change out a large sprocket by hand? Light weight, segmented teeth sections can be bolted on to a fixed or split hub, for quick and easy change out. Usually in 3-5 pieces.

All sprockets can be fabricated to suit your individual requirements. Tooth count & profiles, bosses, bores, taper locks, keyways & set screws for both drive & idler sprockets.

Sprockets available to suit a vast range of conveyor chains: mill, drag, malleable, transfer, double flex, rooftop, power transmission, trimmer, OSB, apron feeder, bucket elevator, engineering class, pintle, sorter, rivetless, 142 series CDM & triple.

Suppliers

Related Products / Services

Whatever you’re

engineering, we can help