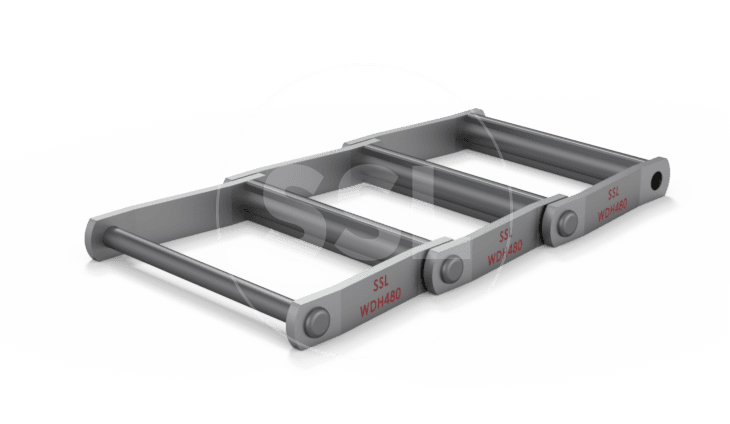

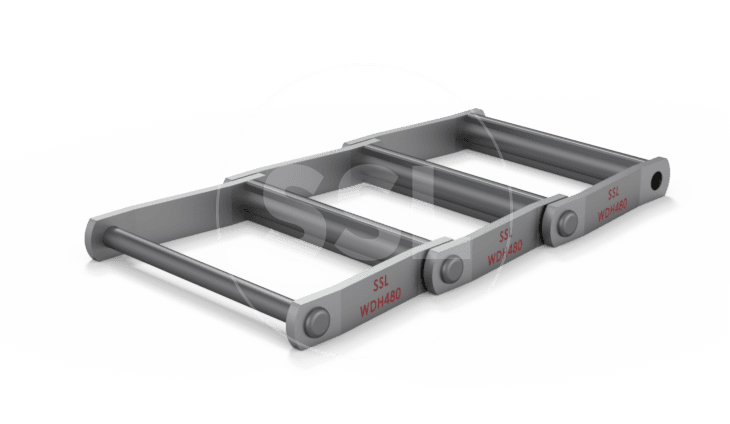

Welded Steel Drag Chains

Availability

5″ to 8″

Standard, Heavy Duty, Super Hog, Whole Hog

10 ft rolls

Yes

Yes

Yes & individual teeth

Features

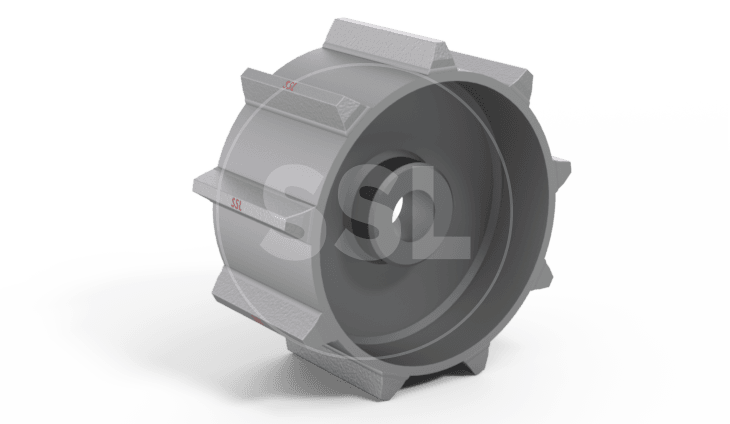

Original formed barrel design for complete rivet to barrel contact for maximum rivet wear, higher impact strength, ease of attachment welding & optional heat treating &/or induction hardening.

With increased pitch sizes, larger rivets & thicker side plates, XHD drag chain nearly doubles the ultimate strength & working loads when compared to standard drag chains.

Featuring a formed, heavy wall seamless tube barrel, this rugged barrel supports a through & induction hardened 1″ rivet. Eliminate crushed/peeled barrels & reduce wear due to racking, Increase conveyor speeds, move heavier loads with less downtime. Also available with heat treated sidebars & barrels.

Designed for brutal applications & two-way operations where only a tough chain will survive, Whole Hog features the same rugged characteristics as Super Hog drag chain but with the addition of an extra heavy duty round barrel, through hardened then induction hardened rivets & through hardened side bars.

Short centred conveyors? We recommend having your CAN-AM drag chain manufactured with reverse barrels so the chain operates wide end forward. This dramatically reduces friction between the sprocket tooth & chain barrel increasing the service life of both the chain and sprocket.

Welded Steel Drag Chain Range

| Pitch Size (inches) | Standard | Heavy Duty XHD | Super Hog | Whole Hog |

|---|---|---|---|---|

| 5.000" | WD102 | - | - | - |

| 6.000" | WD104 WD110 WD120 | WD120XHD | WDRS120-SH | - |

| 8.000" | WD112 WD116 WD118 WD122 WD480 | WD118XHD WD122XHD WD480XHD | WDRS118-SH WDRS118-XHDSH WDRS122-SH WDRS122-XHDSH WDRS480-SH WDRS480-XHDSH | WDRS118-WH WDRS118-XHDWH WDRS120-WH WDRS120-XHDWH WDRS122-WH WDRS122-XHDWH WDRS480-WH WDRS480-XHDWH |

Suppliers

Related Products / Services

Whatever you’re

engineering, we can help