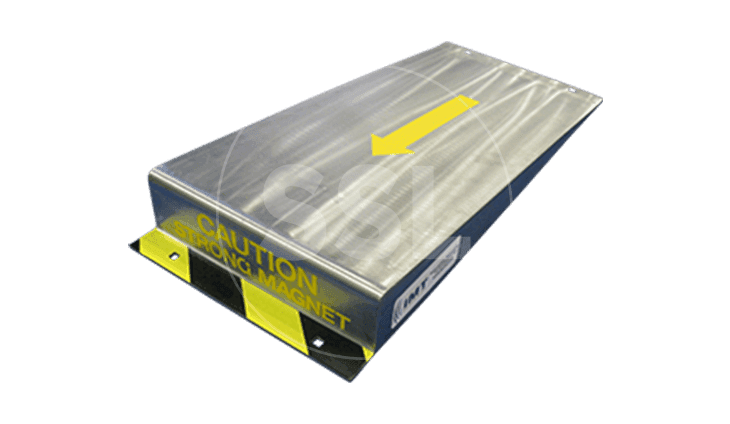

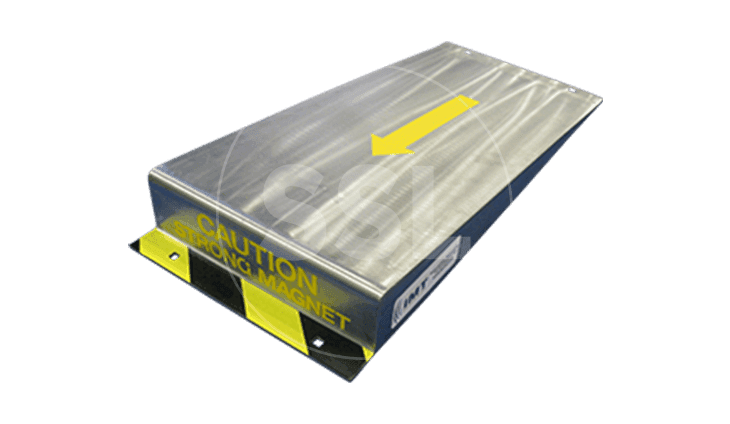

Tramp Metal Magnet – Low Cost Contamination Solution for Vibratory Feeders and Conveyors

Rare Earth Tramp Metal Separator for Vibratory Feeders and Conveyors.

Innovative Magnetic Technologies, Inc. has developed a low cost solution to tramp metal contamination in hog and chipper vibratory conveyors. The Vibra-Sep™ attracts and retains ferrous tramp metal from the product stream prior to entering metal detection equipment.

This provides enhanced metal detector performance by reducing unnecessary tripping, and allowing operations to run at higher sensitivity levels without annoying shutdowns.

“A typical chipper in-feed situation is as follows,” states David Miles, President of Innovative Magnetic Technologies, Inc. “as tramp metal crosses over the metal detector, the metal detector shuts down the conveyor, signaling production/maintenance personnel to investigate and physically search the conveyor to find and remove the tramp metal that cause the stoppage.

Some metal detection tripping situations are caused by smaller tramp that is considered acceptable to run through the process. Personnel find these metal detection trips a nuisance and have a tendency to reduce the metal detectors sensitivity/effectiveness to the point where tramp metals are allowed to pass by the metal detector.

This reduced sensitivity can cause damage ranging from chipper knives damage to more catastrophic situations such as fires and equipment failure. By reducing the nuisance trips, operators are not pulled away from there other duties and can focus on other facets of production and or maintenance.

Also by extracting the smaller tramp metal pieces, chipper knifes remain sharp longer and produce better chip quality, reducing fines/pins.

The Vibra-Sep™ utilizes a Neodymium Iron Boron (rare earth) permanent magnetic core that is situated within the all stainless steel shell and requires no electrical connections. The magnetic attraction is focused upward into the product burden and also on the vertical face, providing an area where tramp metal can be magnetically retained and is easily accessible for cleaning.

This extremely effective separator is enhanced by the vibrating action of the conveyor. As conveyed material is agitated, the tramp metal has a tendency to migrate to the conveyor pans floor where the Vibra-Sep™ is situated, providing an optimum separation situation.

The Vibra-Sep™ utilizes a simple to install mechanical fastening system. Installation is accomplished in minutes, as the separator comes predrilled and is supplied with all the necessary hardware and installation instructions.

Vibra-Sep™ is available in all conveyor widths and the more common sizes 12″, 18″ and 24” are typically stocked at the IMT manufacturing facility in Kelowna, BC. Canada.

To date, Vibra-Sep™ has been installed in numerous applications in Canada, USA and New Zealand.

Vibra-Sep™ provides increased up-time, higher chip quality, enhanced knife life, decreased maintenance costs and reduced risk of injury to plant personnel.

The Vibra-Sep™ vibratory magnetic separators are a very popular magnetic product due to their simple installation and are easily customisable to any application requirements.

Capture Tramp Metal

Reduce Metal Detector Tripping

High Performance and Budget Friendly

Click through to read the Vibra-Sep™ product page.

From belt magnets to magnetic conveyors, IMT offers a wide range of magnetic equipment for mining & mineral processing, wood processing and bulk material handling applications. Tramp metal magnets provide continuous protection for processing equipment by removing ferrous materials which may cause costly damage and product contamination.

Download the Vibra-Sep™ product PDF below.

To browse the full range of IMT’s magnetic separation and material handling process equipment for heavy industry, click the link.

Supply Services Limited is the exclusive distributor of IMT’s quality magnetic product range in New Zealand.

We look forward to discussing your application and requirements. Contact our nationwide team, toll free on 0800 102 112.