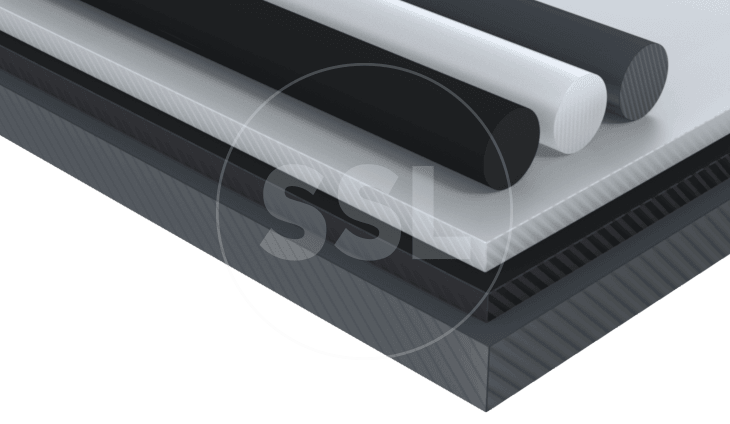

Rigid PVC

Availability

10mm to 350mm OD

5mm ID to 230mm OD

1mm to 50mm Thick

Grey, Black, White

No

Yes, however some grades have minimum order quantity

Features

Rigid PVC is a low-cost material with good mechanical strength, excellent chemical resistance, corrosion resistance & electrical insulation that is easy to machine. This cost to performance ratio makes PVC a cost-effective material of choice for several industries including construction, electrical & chemical.

Rigid PVC offers excellent chemical and corrosion resistance. PVC is resistant to most acids, alkalis, salts, alcohols & fats. Ask one of our technical solutions specialists if PVC is suitable for your chemical application. PVC’s durability & resistance to rot & corrosion makes PVC a long-lasting alternative material.

Rigid PVC is suitable for a broad range of applications over numerous industries. Examples include but are not limited to: manifolds, pump parts, cabinets, lab equipment, chemical storage, tanks, electrical insulation, space packers, concrete mould forms, valves, handles and knobs, trays, backing boards.

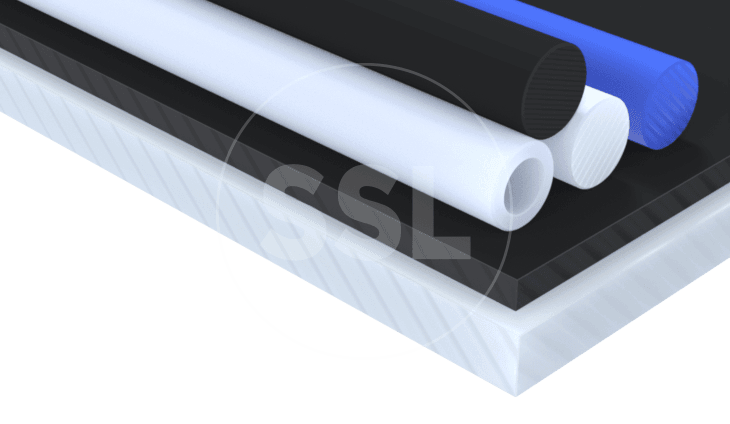

Rigid PVC Range

| Product Type | Industry Usage | Available Products & Notes |

|---|---|---|

| Rigid PVC Unplasticised (PVC-U) | General & Chemical Industries Electrical Industries Pumps & Valve Bodies Electrical Backing Boards Chemical Components Etc. | Rod, Tube & Sheet Grey, Black & White |

Want to know more?

Check out this recent blog post about rigid PVC rod and sheet.

Due to the characteristics and price point of rigid PVC, it’s a very versatile and highly utilised engineering plastic material.

Related Products / Services

Whatever you’re

engineering, we can help