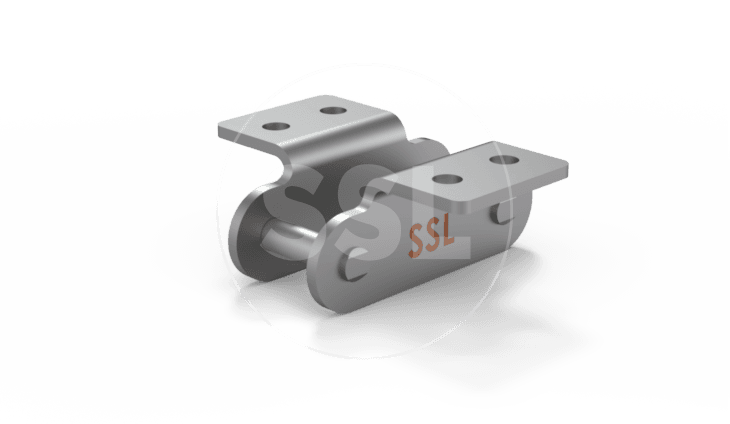

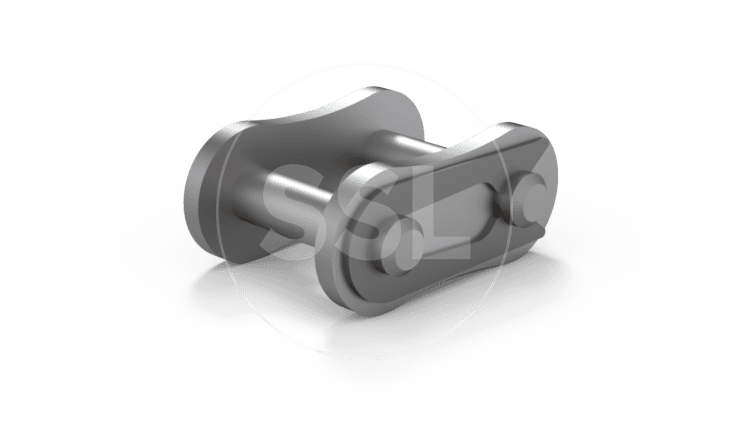

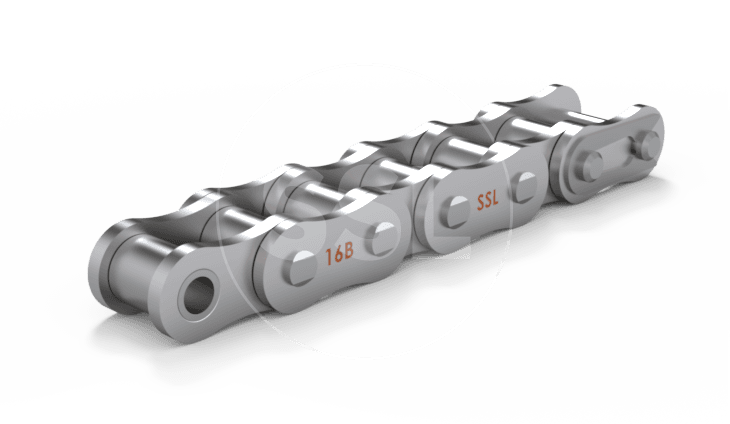

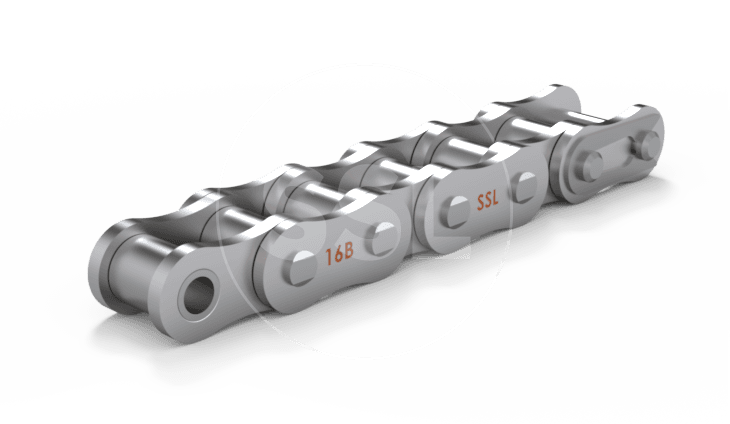

Stainless Steel Roller Chains

Availability

5/16″ to 1″

Simplex, Duplex, Triplex

10ft boxes or 50ft rolls

Yes

Yes

Yes

Features

For medium strength, medium corrosion resistance. Provides corrosion resistance far beyond the capabilities of standard roller chains. Ideal for use in water, alkali or acid environments.

For low strength, high corrosion resistance. Provides superior corrosion resistance in harsh conditions to the 304 series stainless steel range.

For high strength, low corrosion resistance. 600 series stainless steel allows for greater working loads & improved wear due to precipitation hardened stainless steel parts.

Available on request

Available on request

Ideal for applications where the chain will come into contact with food

Stainless Steel Roller Chain Range

| Pitch Size (inches) | American Standard (ANSI) | British Standard (BS) |

|---|---|---|

| 5/16" | - | 05B-1SS |

| 3/8" | 35-1SS | 06B-1SS 06B-2SS 06B-3SS |

| 1/2" | 40-1SS 40-2SS 41-1SS | 08B-1SS 08B-2SS 08B-3SS |

| 5/8" | 50-1SS 50-2SS | 10B-1SS 10B-2SS 10B-3SS |

| 3/4" | 60-1SS 60-2SS | 12B-1SS 12B-2SS 12B-3SS |

| 1" | 80-1SS | 16B-1SS 16B-2SS 16B-3SS |

| *more sizes on request |

Suppliers

Related Products / Services

Whatever you’re

engineering, we can help