PEEK Plastic

Availability

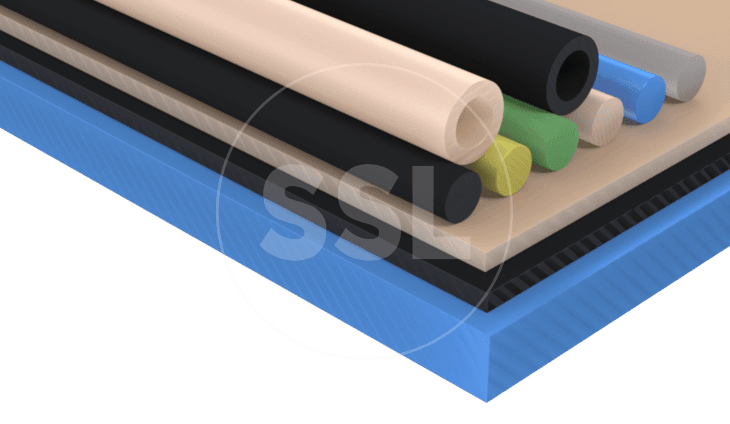

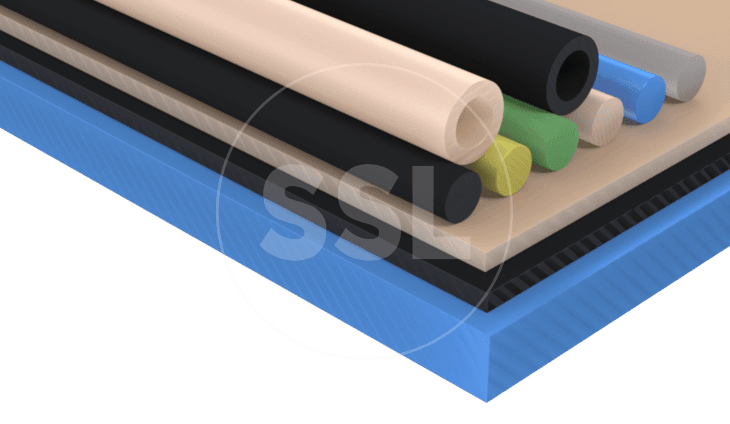

4mm to 210mm OD

16mm ID to 310mm OD

5mm to 150mm Thick

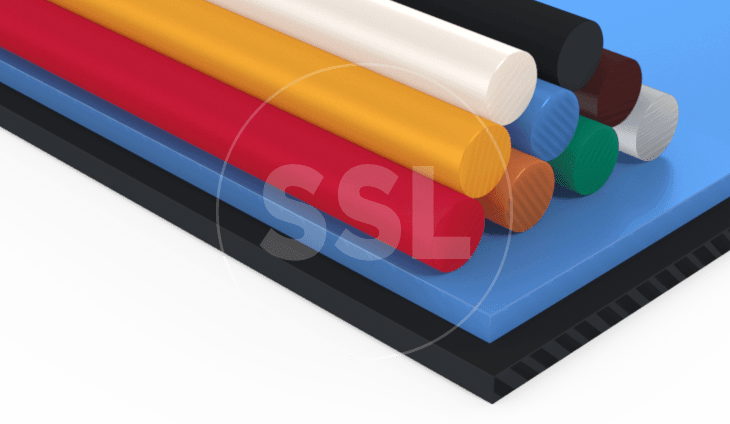

Beige, Black, Grey, White, Blue, Green, Yellow, Ivory

Yes

Yes, however some grades have minimum order quantity

Features

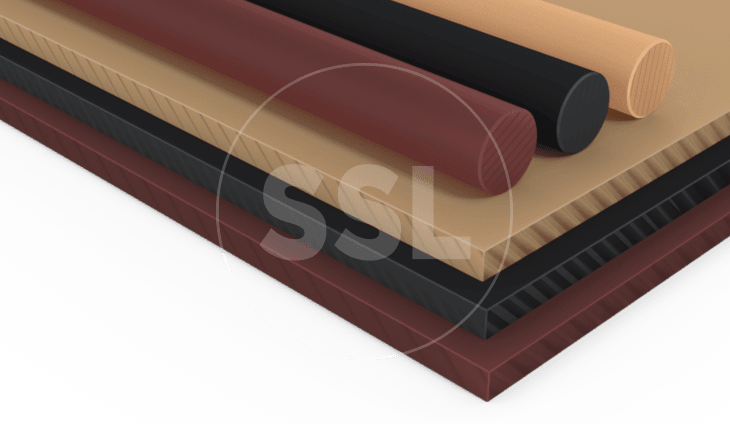

Semi-crystalline PEEK plastic is utilised in industries such as electronics, mechanical engineering, automotive, conveyor technics, medical, food, packaging & the oil-gas industries. A vast range of TECA PEEK grades & colours are available to specifically meet the requirements of these industries.

PEEK plastic is available in a range of standard grades through to the advanced medical, food, electrical or oil & gas grades. Our TECA PEEK range reinforced grades such as: glass, ceramic, carbon fiber, mineral, bearing or wear additives. We also have electrically conductive, metal detectable, bio compatible & extra high temperature grades.

PEEK plastic is a thermoplastic that is used in a vast range of applications too numerous to list. Insulators, connectors, gears, sliding parts, compressor & pump parts, drives, rollers & bushings. Gearbox components, impellers, surgical instruments & implants, valves & valve seats, kneaders, drill heads, seals, bearings.

PEEK Plastic Range

| Product Type | Industry Usage | Available Products & Notes *Some items are manufactured & imported on request |

|---|---|---|

| TECA PEEK Natural & Black | Chemical, Mechanical, Energy, Electronics, Food, Oil & Gas, Aircraft & Aerospace, Automotive, Semi-Conductor, Vacuum technologies | Natural Rod, Tube & Sheet Beige & Black FDA, EU10/2011, ISO 23936-1 & Aerospace FAR 25.853 approvals |

| TECA PEEK GF30 Natural | Chemical, Mechanical, Electronics, Oil & Gas, Aircraft & Aerospace, Automotive, Vacuum technologies | Natural Rod & Sheet, Glass filled 30% Beige ISO 23936-1 & Aerospace FAR 25.853 approval |

| TECA PEEK CF30 Black | Chemical, Mechanical, Oil & Gas, Aircraft & Aerospace, Automotive, Vacuum technologies | Rod & Sheet, Carbon filled 30% Black Aerospace FAR 25.853 approval |

| TECA PEEK PVX Black | Chemical, Mechanical, Energy, Aircraft & Aerospace, Automotive technologies *High performance bearing grade | Rod, Tube & Sheet, 10% PTFE filled, 10% Graphite filled, 10% Carbon filled Black Aerospace FAR 25.853 approval |

| TECA PEEK ID | Food, Mechanical technologies *Inductively Detectable | Rod & Sheet, Metal Detectable filler BlueGrey FDA, EU10/2011 approvals |

| TECA PEEK CMF Grey | Mechanical, Electronics, Semi-Conductor, Vacuum technologies | Rod & Sheet, Ceramic filled Grey & White |

| TECA PEEK TS | Mechanical, Electronics, Semi-Conductor, Vacuum technologies | Rod & Sheet, Mineral filled BlueGrey |

| TECA PEEK ELS Nano Black | Mechanical, Electronics, Aircraft & Aerospace, Semi-Conductor, Computer technologies *Electrically Conductive | Rod & Sheet, Carbon Nano Tubes to allow conductivity Black |

| TECA PEEK TF10 Blue | Mechanical, Food, Automotive, Chemical technologies | Rod & Tube, 10% PTFE filled Blue FDA, EU10/2011 approvals |

| TECA PEEK HT | Mechanical, Conveyor, Automotive, Chemical technologies *High Temperature Grade (additional 30°C higher than standard PEEK) | Rod & Sheet Black |

| TECA PEEK ST | Mechanical, Automotive, Chemical technologies *Higher Glass Transition Temperature, Higher Strength & Loading Capacity | Rod & Sheet Black |

| TECA PEEK MT | Medical, Mechanical, Food technologies *Bio-compatible for medical applications | Rod & Sheet Black FDA, ISO 10993-1, -4, 5, -18 approvals |

| TECA PEEK MT Classix White | Medical technologies *Bio-compatible for dental & medical applications | Rod CreamWhite FDA, ISO 10993-1, -4, -5, -18 approvals |

| TECA PEEK SE & CMP | Semiconductor technologies | Tube Beige. Natural |

| TECA PEEK SD Black | Semiconductor technologies *Electrostatic Dissipative | Sheet, Electrically Modified Black |

Want to learn more?

About our range of high performance PEEK plastics?

Make lighter, stronger and more chemically resistant parts that will last longer.

Watch this video on YouTube to find out more about the performance characteristics of PEEK.

Suppliers

Related Products / Services

Whatever you’re

engineering, we can help