Split Sprockets

Why Use Split Sprockets?

Split sprockets are the ideal sprocket especially in areas of limited working space. They are simple and easy to assemble in hard to get areas. Our range of split sprockets for conveyor and wood processing chains allow for the sprocket to be assembled without having to dismount the shaft assembly.

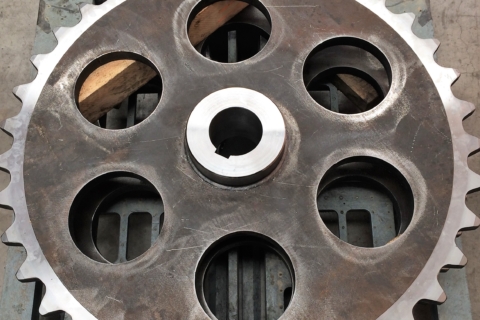

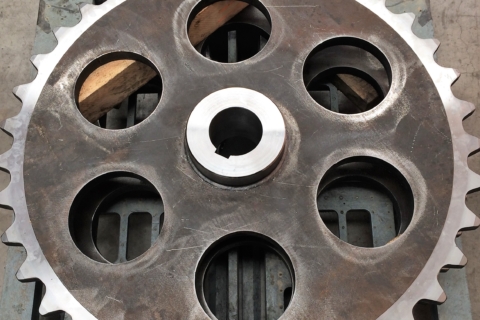

Large sprockets such as conveyor chain sprockets can weigh hundreds of kilograms and are difficult to handle and install. Cranes are often required to lift the sprockets into place for installation. This is where split sprockets and bolt on segmented teeth come into their own. We have clients who no longer require a crane for sprocket installation as the split sprocket being in two halves can now be man-handled for installation.

What Can We Do?

Our fabrication and machine shops can customise your sprockets to suit your application.

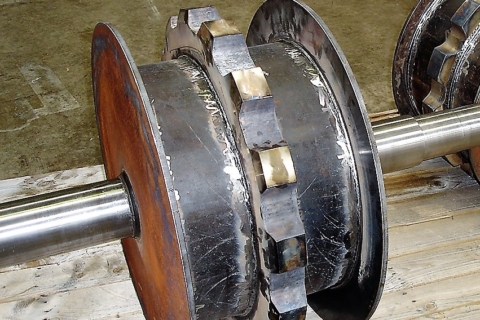

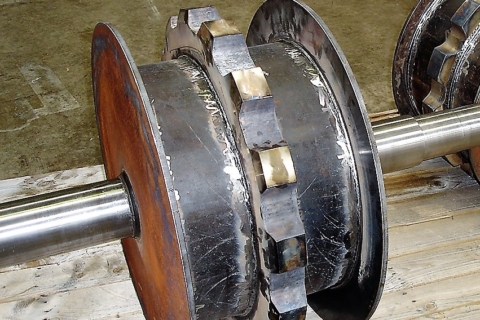

Our sprockets are profile cut and machined as one whole sprocket before being split to ensure a perfect match. We offer B and C type boss styles, but we recommend C type (hub both sides) to stop the sprocket from twisting.

All sprockets can be fabricated to suit your individual requirements. Tooth count & profiles, bosses, bores, taper locks, keyways & set screws for both drive & idler sprockets.

Want to be able to change out a large sprocket by hand? Light weight, segmented teeth sections can be bolted on to a fixed or split hub, for quick and easy change out. Usually in 3-5 pieces.

A range of materials are available to suit the sprockets application. Mild steel, Hardox 400, induction hardened C1045 , stainless steel, polyurethane, nylons, UHMWPE, acetals and composites.

Have you seen our huge range of welded steel mill and drag chains?

What about our range of on the shelf and custom fabricated sprockets?

Check out what Wikipedia says about sprockets.

Have a read about our range of 81X chain, sprockets and accessories.

If you are looking for a NZ based sprocket supplier, check out this blog post.